Viscoelasticity is an essential property of materials that possess both elastic and viscous characteristics. Unlike purely elastic solids, which immediately return to their original shape after deformation, and purely viscous fluids, which flow under stress, viscoelastic materials combine these two behaviors.

This characteristic is crucial in many fields, including biomechanics, materials engineering, polymers, and even the food industry. Understanding viscoelasticity allows for the optimization of material design and use based on the mechanical stresses to which they will be subjected. This first part explores the scientific foundations of viscoelasticity, detailing its principles, its representation models, and the factors influencing its behavior.

YesWeLab supports manufacturers in the analysis and characterization of the viscoelastic properties of their materials through its network of partner laboratories, offering tailor-made solutions to meet technical and regulatory requirements.

1. Understanding viscoelasticity

Definition and fundamental concepts

Viscoelasticity refers to the ability of a material to behave simultaneously as an elastic solid and a viscous fluid when subjected to mechanical stress. This dual nature means that these materials can deform and partially or fully recover their original shape after the stress is removed.

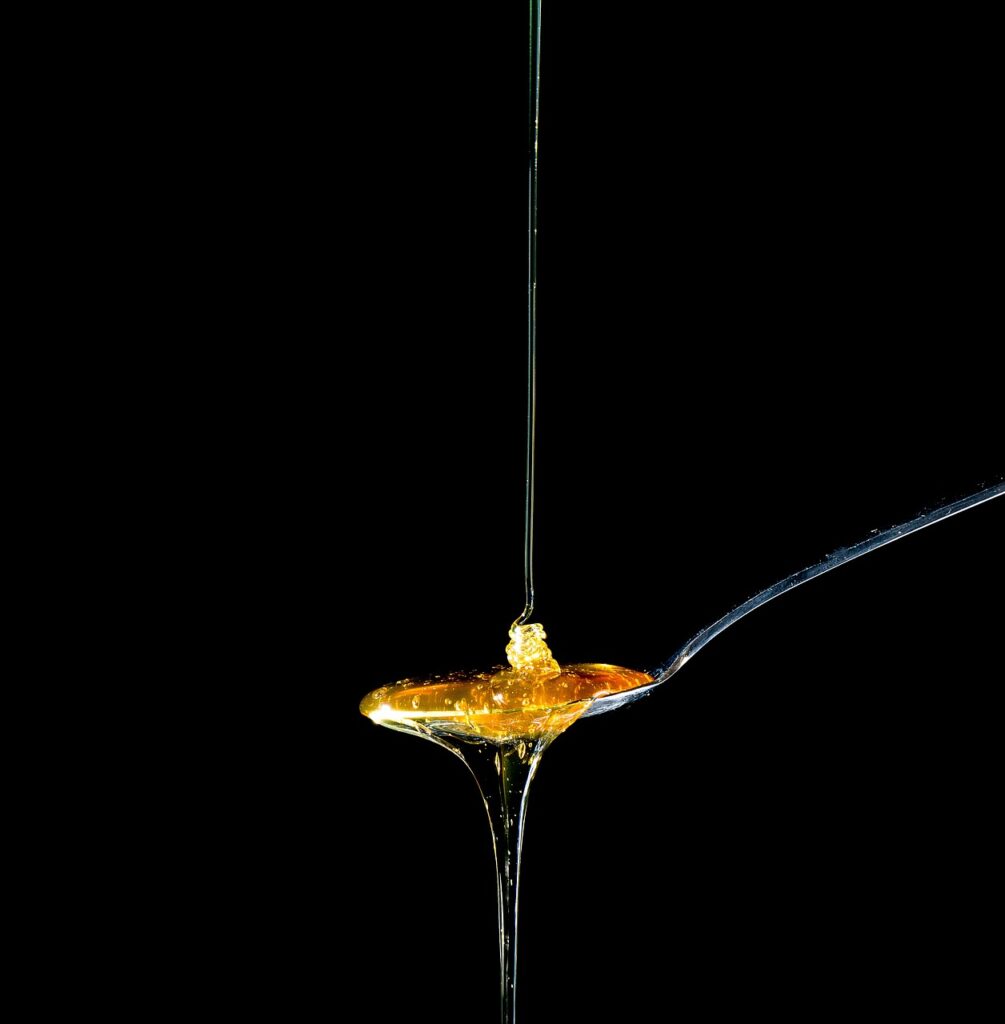

A purely elastic material, like an ideal spring, stores energy when deformed and releases it completely when it returns to its original state. In contrast, a viscous fluid, such as oil or honey, dissipates all applied energy as heat, preventing any energy release.

Viscoelastic materials fall between these two extremes. Under the action of an applied force, they exhibit delayed deformation , which depends on the time and conditions of stress application. This behavior is particularly studied in rheology, a discipline that analyzes the mechanical response of materials to forces exerted upon them.

One of the key aspects of viscoelasticity is its time dependence . Unlike purely elastic materials, which react instantaneously to a force, viscoelastic materials exhibit a delayed response, which manifests itself in two main forms:

- Creep : a gradual deformation under constant stress. For example, a piece of rubber suspended from a mass will gradually elongate under the effect of the weight.

- Stress relaxation : a decrease in applied stress when deformation is held constant. This occurs, for example, in polymer seals that gradually adapt to the shape of a surface after prolonged compression.

This dynamic behavior is at the heart of many industrial applications, particularly in the design of damping materials and medical devices.

Viscoelasticity modeling

elastic and viscous elements to represent a material's response to mechanical stress.

- Maxwell's model : This model represents a viscoelastic material as a spring (elastic element) in series with a damper (viscous element). It is particularly useful for describing materials that exhibit significant creep . Under sudden stress, the spring deforms immediately, but the damper gradually dissipates the energy, resulting in continuous deformation over time. This model is well-suited to viscoelastic fluids such as molten polymers or certain resins.

- The Kelvin-Voigt model : Here, the spring and the damper are arranged in parallel. Unlike the Maxwell model, this model describes materials that better resist instantaneous deformations. When a stress is applied, the damper immediately limits the deformation, and elasticity allows a gradual return to the initial state once the stress is removed. This model is often used to describe damping solids , such as protective foams or polymer materials used in biomedical engineering.

- The Zener model (or solid standard model) : It combines the characteristics of the Maxwell and Kelvin-Voigt models, allowing for a more realistic representation of the behavior of solid viscoelastic materials. It is commonly used to model materials such as engineering rubbers , biological tissues, and certain metallic alloys.

These models make it possible to anticipate the response of materials in various industrial contexts and to design products better suited to real conditions of use.

Factors influencing viscoelastic behavior

Several parameters influence the viscoelastic response of a material, including temperature , strain rate , and duration of stress application .

- Temperature : Viscoelasticity is strongly influenced by temperature. In general, an increase in temperature reduces elasticity and promotes more viscous behavior. For example, thermoplastic polymers become more fluid at high temperatures, facilitating their shaping in industrial processes such as extrusion or injection molding. Conversely, a decrease in temperature stiffens materials and limits their ability to absorb energy.

- Strain rate : When stress is applied rapidly, the material reacts more elastically, temporarily storing energy before releasing it. Conversely, under slow and prolonged stress, viscous behavior predominates, resulting in greater deformation.

- Duration of stress application : The longer the stress is applied, the more the viscous component of the material becomes apparent. This is why structures subjected to prolonged loads, such as seals or medical prostheses, must be designed to resist creep over long periods.

These parameters are crucial in the design of industrial materials and must be taken into account when selecting materials for a given application.

A thorough understanding of viscoelasticity and its models makes it possible to optimize the use of materials in various fields, ranging from biomechanics to construction, including aeronautics and the manufacture of medical devices.

2. Viscoelastic materials and their applications

Viscoelasticity is a key property found in many natural and synthetic materials. It gives them unique characteristics, such as the ability to absorb shocks, deform under prolonged stress, and gradually return to their original shape after the applied force is removed. These properties are widely used in various industrial sectors, ranging from biomedical engineering and aerospace to cosmetics and food processing .

Examples of viscoelastic materials

Viscoelastic materials fall into two main categories: natural , which exist in living organisms and certain mineral structures, and synthetic , designed for specific industrial applications.

| Natural | Synthetics |

| Biological tissues (tendons, ligaments, cartilage) | Polymers and plastics |

| Drink | Memory foam |

| Natural rubber | technical elastomers |

- Natural viscoelastic materials

- Biological tissues such as tendons and ligaments possess viscoelasticity, which allows them to absorb shocks and gradually return to their original length after stretching. This property is essential in biomechanics, particularly for the design of implants or joint prostheses.

- Wood progressively , an important phenomenon to consider in construction and furniture making.

- Natural rubber , derived from latex, is a highly viscoelastic material that absorbs energy and returns to its shape after deformation.

- Synthetic viscoelastic materials

- Polymers and engineering plastics are ubiquitous in industry due to their adaptable properties. For example, flexible PVC and polyurethanes are used in applications requiring controlled flexibility.

- Memory foam , initially developed by NASA, is a viscoelastic polymer used in mattresses and protective equipment. Its ability to absorb and redistribute pressure makes it an essential material in the medical and sports fields.

- Technical elastomers , such as silicone or synthetic rubbers, are commonly used in seals, shoe soles, or anti-vibration devices.

Industrial applications of viscoelasticity

Viscoelastic materials find applications in many industrial sectors. Their properties make it possible to address issues of mechanical strength, shock absorption, flexibility, and long-term stability.

- Biomedical engineering and medical devices

- In biomechanics, the viscoelasticity of biological tissues is a key factor in the design of joint prostheses and vascular implants . Materials must mimic the mechanical response of living tissues to ensure optimal comfort and successful integration within the body.

- Injectable gels , such as those used in aesthetic medicine (e.g., hyaluronic acid for filling wrinkles), must have an optimal balance between elasticity and viscosity to ensure good hold and a natural result.

- Automotive and aerospace industry

- Viscoelastic materials are used to reduce vibration and noise in vehicles and aircraft. Rubber shock absorbers and help to dampen impacts and improve passenger comfort.

- In aviation, certain viscoelastic polymers are integrated into structures to absorb deformations due to variations in pressure and temperature.

- Cosmetics and product formulations

- Viscoelasticity is a key parameter in the formulation of cosmetic creams and gels . For example, the texture of a cream must be viscous enough for pleasant application, while retaining a certain elasticity for better adhesion to the skin.

- Hair products , particularly styling gels and mousses, exploit these properties to ensure a flexible and long-lasting hold.

- Construction materials and earthquake protection

- In civil engineering, viscoelastic damping devices are integrated into the structures of buildings and bridges to absorb seismic vibrations. These materials help limit damage by dissipating the energy of the shocks.

- Acoustic coatings based on viscoelastic polymers are used to reduce noise transmission in homes and public spaces.

- Food processing and packaging industry

- Viscoelasticity plays a crucial role in the texture of food products. For example, the consistency of sauces and creams depends on the viscoelastic response of the ingredients, influencing their spreadability and stability.

- In the field of food packaging , viscoelastic plastics must guarantee good mechanical resistance while remaining sufficiently flexible for the intended use.

The use of viscoelastic materials is ubiquitous in modern industry, improving the comfort, safety, and efficiency of everyday products. These properties are also crucial in laboratory analyses, where characterizing viscoelasticity allows for optimizing material performance and ensuring compliance with applicable standards.

Are you looking for an analysis?

3. Laboratory analyses of viscoelasticity

The study of viscoelasticity is essential for understanding the behavior of materials and ensuring their performance in various industrial applications. To characterize this property, laboratories use advanced techniques that allow them to measure the mechanical parameters influencing the deformation and dynamic response of materials. These analyses are particularly important in sectors such as aerospace, biomechanics, food processing, and cosmetics, where texture, strength, and energy absorption play a key role.

Analytical procedures: techniques for measuring the viscoelasticity of materials

Materials analysis laboratories use various methods to characterize viscoelasticity. These techniques allow for the measurement of the elastic modulus , viscosity , energy absorption capacity , and other parameters influencing a material's mechanical response.

Dynamic Mechanical Analysis (DMA)

This method is one of the most widely used for studying viscoelasticity. It consists of applying an oscillating stress to a material and measuring its response as a function of temperature, frequency, and deformation amplitude.

- Measurement of the conservation modulus (G') , representing the elastic part of the material.

- Measurement of the loss modulus (G'') , corresponding to the dissipation of energy in the form of heat.

- Calculation of the damping factor (tan δ = G''/G') , indicating the balance between elastic and viscous . DMA is widely used for the study of polymers, biomaterials and industrial coatings.

Oscillatory shear rheometry

This technique is used to analyze the response of a material to shear deformations. It is particularly well-suited to viscoelastic liquids and gels, such as cosmetic creams, polymer solutions, and industrial inks.

- Study of the complex viscosity of the material as a function of the frequency of application of the stress.

- Determination of relaxation time and behavior under various flow regimes.

Creep and stress relaxation tests

These tests allow us to measure the evolution of deformation or stress over time under a constant load.

- Creep test : the material is subjected to a fixed stress and its progressive elongation is observed.

- Stress relaxation test : a fixed deformation is imposed and the progressive decrease in internal stress is measured. These analyses are particularly useful for polymers, rubbers and construction materials subjected to prolonged loads.

Thermomechanical tests

The effect of temperature on viscoelasticity is a key parameter in materials design. Thermomechanical testing (TMA) allows measurement of thermal expansion, glass transition, and changes in behavior under controlled thermal stresses.

Laboratory analyses thus make it possible to precisely characterize the viscoelastic behavior of materials and to optimize their formulation according to industrial needs.

Importance of regulatory compliance testing (ISO 17025, COFRAC standards)

Viscoelastic analyses must be carried out in accordance with strict standards to ensure the reliability of the results and their industrial relevance.

- ISO 17025 standard : This standard defines the requirements for the competence of testing and calibration laboratories. An ISO 17025 accredited laboratory guarantees the traceability of results and their compliance with regulatory requirements.

- COFRAC accreditation : In France, laboratories must be accredited by the French Accreditation Committee (COFRAC) to ensure the validity of analyses carried out on viscoelastic materials.

- Industry-specific standards :

- Automotive industry : standardized tests to guarantee resistance to vibration and shock.

- Cosmetics : compliance with European regulations on the stability of gels and creams.

- Food industry : quality standards for food packaging and formulations.

Adhering to these standards is essential to ensure product reliability, optimize performance, and guarantee safe use.

Migration tests for materials in contact with foodstuffs (EC Regulation No. 1935/2004, FDA standards)

Viscoelastic materials are commonly used in food packaging and industrial coatings. It is therefore crucial to verify that these materials do not transfer undesirable substances to the food they contain.

Global and specific migration tests

- Assessment of the total quantity of substances that can be released by a material in contact with food.

- Analysis of the migration of specific compounds (e.g., plasticizers, additives, residual monomers).

Regulation (EC) No 1935/2004

This European regulation imposes strict controls on materials that come into contact with food. The tests must guarantee that these materials do not alter the organoleptic properties of food and do not pose any risk to consumer health.

FDA (Food and Drug Administration) standards

In the United States, materials used for food packaging must comply with FDA regulations. Laboratories conduct migration tests to ensure that this packaging meets US safety requirements.

Migration analyses are essential to ensure regulatory compliance and guarantee the safety of materials used in the food industry.

Rheological testing: analysis of the fluidity and texture of food and cosmetic products

Viscoelasticity plays a fundamental role in the texture and fluidity of food and cosmetic products. Rheological tests allow for the optimization of these formulations, ensuring mechanical properties suited to their intended use.

- Optimizing the texture of food products

- Study of the fluidity and spreading of sauces, creams and dairy products.

- Adaptation of formulations to guarantee better stability over time.

- Tests on cosmetic products

- Evaluation of the consistency of creams and gels according to temperature and humidity.

- Analysis of distribution and adhesion on the skin to improve the effectiveness of formulas.

Rheological testing is a key tool for adjusting formulations and ensuring an optimal user experience.

Laboratory analyses of viscoelasticity are essential for optimizing material formulations and ensuring compliance with industrial requirements. They allow for adapting the mechanical properties of products to the specific needs of each sector, thus ensuring their effectiveness and safety.

4. Why use YesWeLab for viscoelasticity analysis?

Viscoelasticity analysis is a major challenge for many industries, requiring in-depth expertise and cutting-edge equipment. Thanks to its network of partner laboratories, YesWeLab offers analytical services tailored to the specific requirements of each sector. Whether for the characterization of polymer materials, the optimization of cosmetic formulations, or the validation of packaging materials, YesWeLab provides customized solutions that comply with international standards.

Expertise and cutting-edge technologies

YesWeLab offers advanced analyses to accurately evaluate the viscoelastic properties of materials.

A network of specialized laboratories

With over 200 partner laboratories , YesWeLab covers a wide range of analyses dedicated to materials characterization. Each laboratory is selected according to criteria of technical competence and certification (ISO 17025, COFRAC), guaranteeing the reliability of the results obtained.

High-precision analytical techniques

YesWeLab provides companies with cutting-edge methods for studying viscoelastic materials:

- Dynamic mechanical analysis (DMA) for measuring the modulus of elasticity and the loss modulus.

- Oscillatory rheometry to characterize the viscosity and shear behavior of fluids and gels.

- Thermomechanical tests (TMA) to analyze the effect of temperature variations on the properties of materials.

- Creep and stress relaxation tests to predict the evolution of a material under prolonged load.

Thanks to these tools, YesWeLab is able to support companies in the validation and optimization of their materials, according to the technical and regulatory requirements of their sector of activity.

Collaboration process with YesWeLab

YesWeLab facilitates access to viscoelasticity analysis by providing an intuitive digital platform. This system allows companies to optimize their analytical management by centralizing the ordering and tracking of laboratory services.

- Identification of analytical needs

- The client describes their needs via the YesWeLab platform.

- An expert analyzes the request and directs it towards the most relevant analysis method.

- Laboratory selection and sample shipment

- YesWeLab identifies the most suitable partner laboratory based on the material and standards required.

- A standardized shipping procedure ensures the traceability and integrity of the samples.

- Performing laboratory analyses

- The tests are carried out according to validated protocols and in compliance with regulatory standards.

- The results are analyzed and formatted into a detailed report.

- Interpretation of results and recommendations

- Companies receive their results via the digital platform.

- YesWeLab experts can assist the client in interpreting the data and propose solutions for optimizing the tested materials.

This process ensures smooth and efficient analysis management, reducing execution times while guaranteeing reliable and actionable results.

Regulatory compliance and support

Viscoelasticity analysis must meet strict regulatory requirements, particularly in the pharmaceutical, cosmetic, and food industries. YesWeLab assists companies in ensuring their products comply with current regulations.

Compliance with current standards

All YesWeLab partner laboratories are accredited according to rigorous standards

Compliance with regulations specific to each sector

- Cosmetics industry : analyses in accordance with European regulation (EC) No. 1223/2009 on the safety of cosmetic products.

- Food packaging : migration tests according to EC Regulation No. 1935/2004 FDA standards .

- Biomedical materials ISO 10993 requirements on the biocompatibility of materials.

YesWeLab helps its clients anticipate regulatory requirements and ensure the conformity of their materials to current standards, thereby reducing the risks of non-compliance and facilitating access to international markets.