Cinnamaldehyde, also called cinnamaldehyde, is an aromatic compound that plays a key role in several sectors, including food , cosmetics , agriculture and industry.

Naturally present in cinnamon essence, it is known for its powerful cinnamon scent, which makes it popular in perfumed and aromatic products.

This article explores the chemical and physical properties of cinnamaldehyde, its uses, and laboratory methods for its analysis. This detailed guide also provides valuable information for understanding its impact in various fields and the precautions to take when using it.

1. Introduction to cinnamaldehyde

Origin and definition

Cinnamaldehyde, or cinnamaldehyde, is an organic compound belonging to the phenylpropanoid family, characterized by a unique chemical structure with a benzene ring and a double bond in the trans position. Its molecular formula is C9H8O, and it is primarily found in cinnamon oil, representing approximately 90% of its composition. This compound is also identified by its CAS number (104-55-2) and its IUPAC name, (E)-3-phenylprop-2-enal.

Cinnamaldehyde is primarily extracted from the trunk of the cinnamon tree, but it is also found in other plant species such as the camphor tree and the Chinese cinnamon tree. Its chemical structure gives cinnamaldehyde an intense cinnamon scent, which is valued in various applications, including food products, cosmetics, and crop protection agents.

Physical and chemical properties

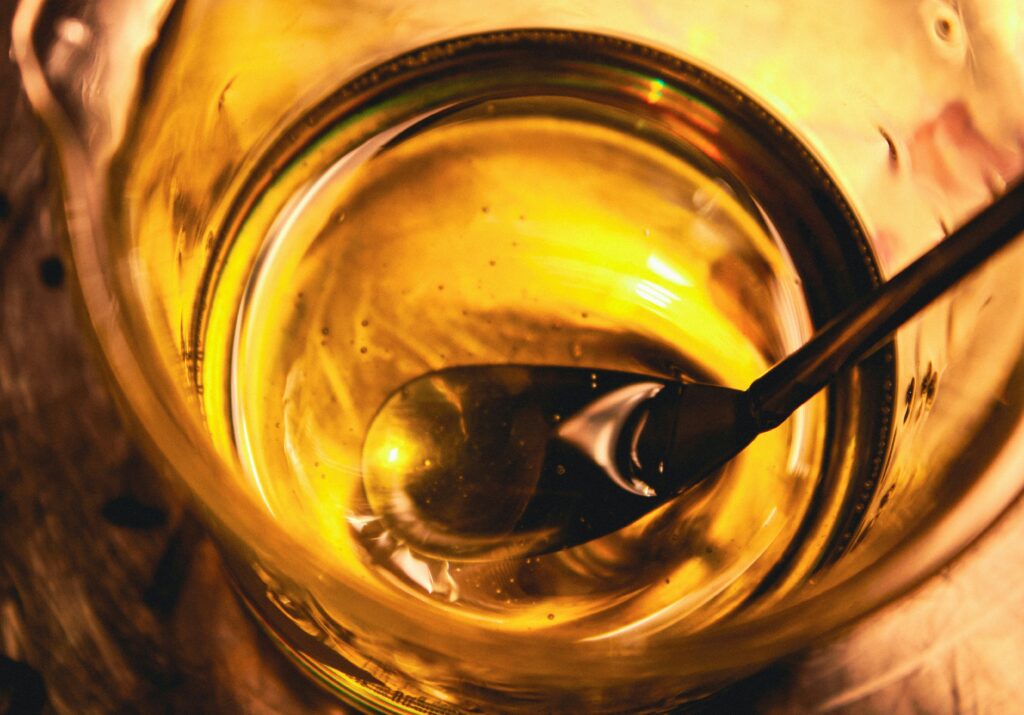

Cinnamaldehyde is a yellow liquid, more viscous than water, which facilitates its handling in the laboratory for analysis and product formulation. Among its important physical and chemical properties are:

- Molar mass : 132.16 g/mol.

- Melting point : -7.5 °C, which makes it liquid at room temperature.

- Boiling point : 248 °C, making it a relatively stable compound under different conditions.

- Solubility : It is slightly soluble in water (1.1 g/L at 20 °C), but exhibits good solubility in organic solvents such as ethanol, ether and chloroform, which facilitates its integration into various formulations.

- pKa : approximately 0.3, which indicates a low tendency to lose a proton in aqueous solution, characteristic of aldehydes.

- Molecular diameter : 0.629 nm, influencing its molecular interactions in formulations.

These physical and chemical characteristics make cinnamaldehyde an interesting compound to handle and analyze in laboratories, where its specific properties are used for various industrial and scientific applications.

Importance of cinnamaldehyde in scientific research and industrial applications

Cinnamaldehyde is a frequent subject of study in scientific research due to its aromatic properties and its ability to interact with microorganisms, notably as a natural antimicrobial agent. These characteristics make it a prized ingredient in food formulations, where it is used as a flavoring and preservative. In cosmetics, it is valued for its warm, spicy scent, which adds an oriental note to many perfumes and lotions.

In agriculture, cinnamaldehyde is also used as a natural fungicide and insecticide, thanks to its ability to repel certain pests and animals, thus contributing to effective crop protection without excessive reliance on synthetic chemicals. Furthermore, in industry, it acts as a corrosion inhibitor for ferrous alloys exposed to corrosive environments, demonstrating its potential for extending the lifespan of metal equipment.

2. What is the purpose of cinnamaldehyde?

Food uses

Cinnamaldehyde is widely used as a food flavoring. Its spicy, cinnamon-like taste makes it especially popular in a range of products, including candies, chewing gum, ice cream, and beverages. As a natural flavoring, it is prized for adding warmth and depth to flavors, while also providing an alternative to artificial flavorings. It is often used in combination with other natural flavorings to create spicy and fruity blends, which are highly valued in desserts and confectionery.

Beyond its aromatic properties, cinnamaldehyde is also known for its antimicrobial effects, which help extend the shelf life of certain food products. By inhibiting the growth of pathogenic microorganisms, it helps ensure food safety without the need for synthetic chemical preservatives. This characteristic makes it a valuable component in perishable products and those requiring long storage times.

Applications in cosmetics

In the cosmetics , cinnamaldehyde is a key ingredient in the creation of perfumes and body care products. Its warm, spicy scent lends an oriental and fruity note to fragrance compositions, which are often used in lotions, creams, and perfumes. Due to its popularity, it is frequently found in personal care products, where it plays a significant role in the overall fragrance.

Cinnamaldehyde also possesses antimicrobial and antifungal properties that contribute to the preservation of cosmetic products. By protecting formulations from microbial contamination, it extends product shelf life and ensures consumer safety. Its ability to inhibit the growth of certain microorganisms is particularly advantageous for water-based products, which are often more susceptible to contamination.

Use in agriculture

Cinnamaldehyde is used as a natural fungicide and insecticide in agriculture. Its repellent action is effective against various pests, including harmful insects and pathogenic fungi that can affect crops. Applied to plant roots or leaves, it helps prevent fungal infections without the need for synthetic chemicals, making it a preferred option in organic and environmentally friendly farming practices.

Furthermore, its use as a natural repellent helps keep certain animals, such as cats and dogs, away from cultivated areas. This ability to protect crops from pests while remaining biodegradable and environmentally friendly makes it a valuable ally for farmers seeking ecological and sustainable solutions.

Industrial applications

In industry, cinnamaldehyde is used for its anti-corrosion properties, particularly in protecting ferrous alloys exposed to corrosive environments. When applied to metal surfaces, it forms a barrier that limits rust formation and extends the lifespan of metal equipment and infrastructure. This application is crucial for industrial sectors requiring corrosion protection, such as the chemical and petrochemical industries.

The properties of cinnamaldehyde as an anti-corrosion agent are particularly interesting for environments exposed to corrosive fluids, where it helps to reduce material degradation while limiting maintenance and replacement costs.

Advantages of cinnamaldehyde as a natural alternative

One of the main reasons for the increasing use of cinnamaldehyde lies in its status as a natural alternative to synthetic compounds. As a plant-based product, it is perceived as safer and more environmentally friendly. In a context where the demand for "green" and "natural" products continues to grow, cinnamaldehyde meets the need for natural ingredients that are less polluting and less harmful to human health and the environment.

Furthermore, its effectiveness as an antimicrobial, fungicidal, insecticidal, and anti-corrosion agent makes it a multifunctional component, reducing the need for multiple chemicals to achieve these objectives. This versatile profile, combined with its safety and sustainability benefits, positions cinnamaldehyde as a preferred option in numerous industrial formulations and applications.

3. Does cinnamaldehyde dissolve in water?

Solubility in different solvents

Cinnamaldehyde is slightly soluble in water, meaning it dissolves only in small amounts in aqueous solutions (approximately 1.1 g/L at 20 °C). This low solubility is due to its molecular structure, which includes a nonpolar benzene ring. Nonpolar molecules tend to dissolve more readily in nonpolar or slightly polar solvents, whereas water, being a polar solvent, is not a favorable medium for the dissolution of cinnamaldehyde.

For this reason, cinnamaldehyde is much more soluble in organic solvents such as ethanol, ether, and chloroform. In formulations where perfect homogeneity is required, such as in cosmetics or certain industrial applications, these organic solvents are therefore preferred for the stable and uniform incorporation of cinnamaldehyde.

Impact of solubility on applications

The low solubility of cinnamaldehyde in water can pose challenges for its use in certain products, particularly in aqueous formulations. In the food industry, for example, it is often necessary to mix cinnamaldehyde with additives or solubilizing agents to achieve homogeneous dispersion, especially in beverages or products with high water content.

Similarly, in cosmetic products, this low solubility in aqueous environments necessitates the use of specific formulation techniques to ensure that cinnamaldehyde is well distributed throughout the final product. Sometimes, it is encapsulated in microspheres or incorporated into emulsion systems to optimize its distribution in lotions and moisturizers.

Synthesis and production of cinnamaldehyde

Natural production by extraction

Cinnamaldehyde is primarily extracted from cinnamon oil, obtained by distilling the bark of certain cinnamon tree varieties, such as Ceylon cinnamon (Cinnamomum verum) and Chinese cinnamon (Cinnamomum cassia). The most common method for obtaining natural cinnamaldehyde is steam distillation, which separates the volatile oil from the other components of the bark.

This extraction method relies on the fact that cinnamaldehyde is a volatile molecule, capable of evaporating under the influence of heat. During distillation, steam passes through the bark and carries with it the volatile compounds, including cinnamaldehyde, which then condense to form a liquid phase. This phase is then separated, and the cinnamaldehyde can be isolated and purified for industrial uses.

Chemical synthesis: what reagents would be used to produce cinnamaldehyde?

Besides natural extraction, cinnamaldehyde can be produced by chemical synthesis. One of the most common methods for its production is the aldol condensation between benzaldehyde (C6H5CHO) and acetaldehyde (CH3CHO). This chemical reaction forms the carbon-carbon bond necessary to build the cinnamaldehyde structure, joining the two starting molecules.

The aldol condensation reaction is advantageous because it is relatively simple to perform and allows the production of large quantities of pure cinnamaldehyde. However, this method requires chemical reagents that are not of natural origin, which can limit its acceptability in industries seeking to prioritize natural ingredients. Chemical synthesis is often reserved for large-scale industrial applications, where the purity and cost of the final product are primary criteria.

Comparison between natural and synthetic production

The natural production of cinnamaldehyde through cinnamon distillation is generally considered more environmentally friendly, as it does not require additional chemical reagents. It also guarantees the compound's plant origin, which is desirable in natural food and cosmetic products.

In contrast, the chemical synthesis of cinnamaldehyde offers a more cost-effective solution for industries requiring large quantities of the compound, without being limited by fluctuations in cinnamon supply. This approach is particularly useful in sectors where natural origin is not essential, and where purity and cost are paramount.

Are you looking for an analysis?

4. Derivative compounds and chemical reactions

Oxidation of cinnamaldehyde: what product results from this reaction?

One of the most common reactions to modify cinnamaldehyde is its oxidation, which leads to the formation of benzoic acid. This transformation usually takes place in the presence of strong oxidants, such as potassium permanganate (KMnO₄) or ozone (O₃).

In this reaction, the aldehyde group (-CHO) of cinnamaldehyde is oxidized to form a carboxyl group (-COOH), producing benzoic acid, a compound of interest in industry for its preservative and antibacterial properties. Benzoic acid is used in food preservatives and also finds applications in the manufacture of plastics and resins. This oxidation to benzoic acid is an important reaction in the field of fine chemicals for various consumer products.

Other chemical reactions: reduction and ester formation

Besides oxidation, cinnamaldehyde can undergo other chemical transformations, including reduction reactions. In the presence of reducing agents such as dihydrogen (H₂) under catalysis, the aldehyde group can be reduced to an alcohol, producing cinnamyl alcohol. This reaction is often carried out under heterogeneous catalysis conditions, where a metal such as palladium or nickel acts as a catalyst.

Cinnamyl alcohol is a compound with a sweet cinnamon scent, commonly used in perfumes and fragrances. Thanks to its stable structure and natural fragrance, it offers an attractive alternative to aldehydes in the formulation of skincare and perfume products.

Cinnamaldehyde can also be involved in esterification reactions. In the presence of a carboxylic acid, cinnamaldehyde can form ester derivatives, which are particularly valued in fragrance compositions. For example, cinnamyl acetate is a common derivative in the perfume industry for its cinnamon and fruity aromas.

Use of cinnamaldehyde derivatives in various applications

Compounds derived from cinnamaldehyde, such as benzoic acid, cinnamyl alcohol, and esters, are highly valued for their specific qualities.

- Benzoic acid : In addition to its role as a preservative in the food industry, it is used as an intermediate in the production of plastics, resins and certain pharmaceuticals.

- Cinnamic alcohol : Its sweet odor and stability make it a preferred component in perfumes and cosmetics, where it contributes to rich and natural scents.

- Cinnamaldehyde esters : Esters bring subtle and sophisticated notes to perfumes, often sought after for high-end products.

5. Laboratory analysis and quantification of cinnamaldehyde

GC-MS Screening

To quantify and characterize volatile compounds such as cinnamaldehyde, laboratories commonly use gas chromatography coupled with mass spectrometry ( GC-MS ). This method is particularly effective for compounds present in very small quantities, as it allows for the separation and identification of molecules by their fragmentation spectra.

The standard procedure for analyzing cinnamaldehyde by GC-MS includes several essential steps:

- Sample collection and preparation : Samples containing cinnamaldehyde are placed in sealed, inert vials, which prevents contamination or evaporation of volatile compounds prior to analysis.

- Limit of quantification (LOQ) : The GC-MS method offers high sensitivity, with a very low LOQ. This precision is crucial for detecting cinnamaldehyde even at low concentrations.

This method, often carried out according to a validated internal method, guarantees reproducibility of results and precision in dosage, essential for regulated products such as cosmetics and food.

The importance of analysis in industrial applications

Rigorous analysis of cinnamaldehyde is essential to meet strict regulatory standards, particularly in the food, cosmetics, and medical device sectors. These tests ensure that cinnamaldehyde concentrations comply with safety thresholds set by authorities, thus protecting consumers from potential risks of irritation or toxicity.

Furthermore, analytical results obtained using methods such as HS-GC-MS and UPLC are essential for formulating stable and homogeneous products where cinnamaldehyde is uniformly distributed without degradation or loss of concentration. Thus, laboratory analysis ensures not only product conformity but also efficacy and safety, strengthening user confidence and brand reputation.

6. Regulations and safety surrounding cinnamaldehyde

Precautions for use and potential risks

Although cinnamaldehyde is naturally occurring, it can pose health risks if handled or used improperly. In high concentrations, it is known to cause skin, eye, and respiratory irritation. Its strong odor, while pleasant, can also be irritating to some sensitive individuals.

Cinnamaldehyde is classified as a flammable compound, with a flash point of -3.15 °C, meaning it can ignite at relatively low temperatures. This property necessitates strict storage and handling precautions to prevent fire hazards. In laboratory and industrial settings, it is recommended to handle it in well-ventilated areas and to avoid prolonged exposure without adequate protection, such as gloves and safety glasses.

Compliance with standards in the food and cosmetics sectors

In the food industry, cinnamaldehyde is regulated as an additive or flavoring. Current standards limit its concentration to prevent adverse effects and ensure its safety in food products. The European Food Safety Authority (EFSA) strictly regulates its use, establishing acceptable daily intakes (ADIs) to avoid risks to human health. Manufacturers must ensure that the cinnamaldehyde content in food products does not exceed these limits to guarantee safe use for consumers.

In the cosmetics industry, cinnamaldehyde is also subject to strict regulations. European regulations (Cosmetics Regulation EC No. 1223/2009) require that cosmetic products containing cinnamaldehyde state its presence on the label, as it is identified as a potential allergen. This labeling requirement aims to inform consumers sensitive to fragrance compounds so they can avoid products that could cause allergic reactions.

The importance of traceability and labeling

To ensure the safety of products containing cinnamaldehyde, traceability and labeling are crucial. Traceability regulations require that every step of the production chain be traceable, from the sourcing of raw materials to the final product. This ensures that safety standards are met throughout the process and facilitates product recalls if necessary.

Labeling plays a vital role in ensuring transparency for consumers. By clearly indicating the presence of cinnamaldehyde, manufacturers enable users to make informed decisions, especially those allergic to fragrance substances. This labeling must also include safety instructions, such as storing in cool, well-ventilated conditions, and warnings about the risks of irritation or flammability.

Manufacturer responsibility and the impact of safety standards

Manufacturers of products containing cinnamaldehyde are responsible for complying with these standards and implementing appropriate safety measures to protect consumers and workers. This includes training employees on cinnamaldehyde handling precautions, using personal protective equipment (PPE), and implementing compliant storage procedures.

The safety standards applied to cinnamaldehyde aim not only to protect consumer health but also to ensure product compliance with international requirements. By adhering to these regulations, companies strengthen their credibility in the market and their commitment to safety and quality, which is crucial for building trust with users and regulatory authorities.