The scanning electron microscope (SEM) is a cutting-edge technology used in many industrial and scientific fields to obtain high-resolution images of a sample surface. Through the interaction between an electron beam and the sample material, this technique allows for precise observation of the topography, chemical composition, and crystal structure of various materials. In this article, we will explore the fundamental working principles of the SEM , its essential components, and its role in modern microscopy.

Table of Contents

Operating principles of the scanning electron microscope

The electron beam and its interaction with the sample

The SEM works by scanning the surface of a sample with an electron beam. Unlike traditional optical microscopes that use light, the SEM uses electrons , which have a much shorter wavelength, allowing for much higher resolution. Upon striking the surface of the sample, the primary electrons interact with the atoms in the material and produce several types of signals, such as secondary electrons, backscattered electrons, and X-rays. These signals are then collected by different detectors, allowing a three-dimensional image of the sample's surface to be reconstructed.

The main components of the MEB

An SEM consists of several key components to create and analyze the sample image. The heart of the SEM is the electron gun, a source that generates a beam of electrons. This beam is steered and focused by a series of magnetic lenses to obtain a thin probe that scans the sample surface. The sample is placed on a sample stage, which can be moved in three directions (X, Y, Z) to explore different areas. Vacuum evacuation is essential in this process, as electrons move efficiently in a low-pressure environment, typically a vacuum of 10^-6 mbar to 10^-2 mbar. Finally, electron detectors collect secondary and backscattered electrons to produce the final image. The most commonly used detector is the Everhart-Thornley detector for secondary electrons.

The void in electron microscopy

One of the fundamental elements of the SEM is the need to create a vacuum in the analysis chamber. This is because electrons must move freely without being scattered by air molecules, which prevents energy loss and ensures high resolution. The vacuum also reduces the interactions of the electron with gases in the air, which could alter the image or prevent observation. The pressure in the chamber can vary, but it should generally be between 10^-6 and 10^-3 mbar for optimal operation. This helps maintain the stability and precision of the electron beam throughout the observation process.

These basic operating principles are essential for understanding how an SEM is able to provide the highest quality images at the nanoscale. The SEM has thus become an essential tool in sectors such as materials analysis, biology, microelectronics, and many other areas of science and industry.

Applications of the scanning electron microscope (SEM)

The scanning electron microscope (SEM) is an extremely versatile tool used in a variety of industrial and scientific applications. Its ability to provide high-resolution images of sample surfaces, while also providing information on their chemical composition and crystal structure, makes it an indispensable instrument in many fields. This section explores the various applications of the SEM, with a focus on the most relevant industrial sectors.

Applications in materials science

SEM is commonly used to characterize materials at the nanoscale, particularly in the field of metals , alloys , and polymers . This technique allows the study of surface morphology, structural defects, and chemical composition of materials. Microcracks , inclusions semiconductor manufacturing , SEM can control the quality of deposited layers and identify contamination or defects that may affect device performance.

Applications in biology and medicine

SEM is also used in biology and medicine , although biological samples require pre-treatment to be viewed under SEM. In biology, researchers use it to examine cellular structures and organelles , such as mitochondria and cell membranes , in high resolution. Because of its ability to observe bacterial interactions and the topography of biological samples, SEM plays a key role in understanding infectious diseases, cellular infections, and therapeutic treatments. In forensic science, it is used to examine biological traces, such as blood and hair , at the microscopic level.

Applications in nanotechnology

Nanotechnology quality of nanoscopic materials used in applications such as electronics, energy, and medicine. It is also used in the manufacturing of nanoscale devices, where precision and material quality are essential to ensure optimal performance.

Applications in composite materials

In the composite materials , SEM is used to examine complex structures and observe the distribution of different phases within materials. The fibers and matrices of composite materials can be analyzed to assess their adhesion , homogeneity , and strength . This allows engineers to design higher-performing materials with optimized mechanical and thermal properties. SEM is also crucial for studying manufacturing defects in composite materials, such as microcracks or air bubbles, which can affect their integrity.

Applications in the environment

Environmental laboratories use SEM to analyze particles and pollutants in air, water, and soil. For example, SEM can identify microplastics in the environment and study their impact on flora and fauna. It is also used to examine pollutant deposits soil surfaces or in aquatic sediments . These analyses are essential for assessing environmental risks and the effects of industrial contamination, thus contributing to environmental protection and improving waste management policies.

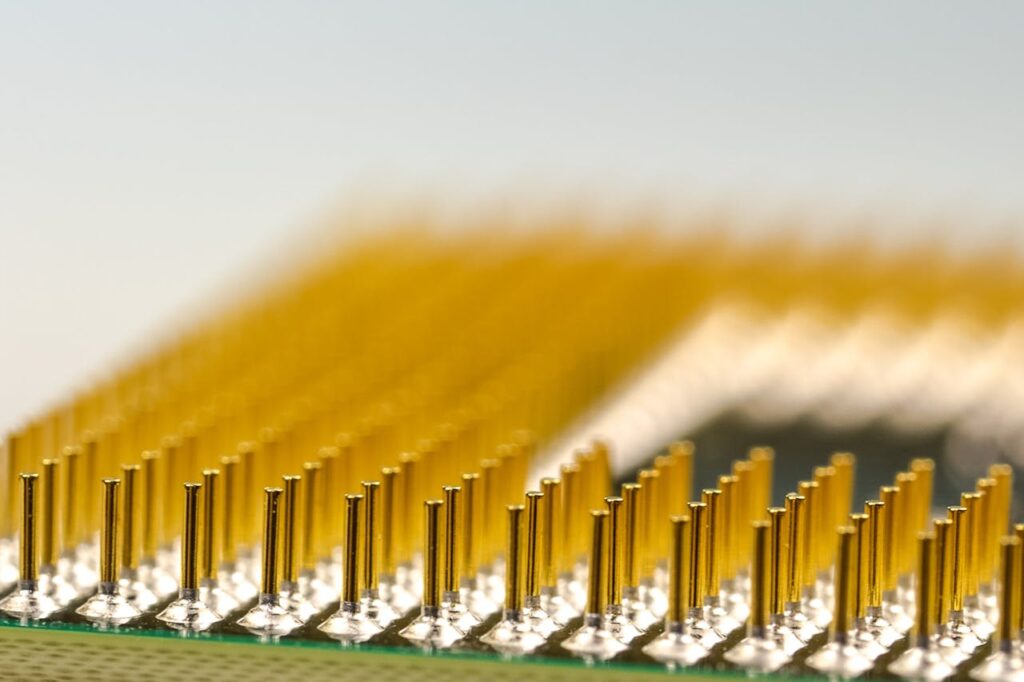

Applications in the electronics industry

In the electronics industry, SEM is used to inspect the manufacturing of electronic chips , printed circuit boards (PCBs), and semiconductor components . It helps control the quality of electrical connections and analyze solder defects that can compromise the performance of electronic products. Thanks to its ability to visualize defects at nanometer resolutions, it is essential to ensure the reliability and longevity of modern electronic devices.

In summary, the scanning electron microscope is a versatile tool with diverse applications spanning sectors as diverse as materials science, biology, nanotechnology, and the electronics industry. Thanks to its ability to provide detailed images and analyze the chemical composition of samples, the SEM is an indispensable instrument for researchers, engineers, and manufacturers seeking high-precision solutions.

Are you looking for an analysis?

Differences between SEM and TEM

The scanning electron microscope (SEM) and the transmission electron microscope (TEM) are two types of electron microscopes used to observe samples at an extremely fine scale. Although they both rely on the use of electron beams to explore matter, these two techniques have fundamental differences, both in how they work and in the specific applications for which they are used.

Operating principle

SEM works by scanning the sample surface with an electron beam, and the resulting secondary or backscattered electrons are collected to generate a three-dimensional image of the sample surface. This process makes it possible to visualize the sample topography and obtain information about its chemical composition through analyses such as X-ray spectrometry (EDX). SEM thus makes it possible to examine relatively thick materials (from a few micrometers to several millimeters), providing an image of the surface and sometimes information about the sample's structure at shallow depths.

TEM , on the other hand, works by passing a beam of electrons through an extremely thin sample (less than 100 nm). The electrons transmitted by the sample are collected and analyzed to create a two-dimensional image that reveals not only the surface structure, but also internal details at the atomic scale. TEM is thus able to provide images with finer resolution than SEM, making it possible to visualize internal structures and details at nanoscales.

Resolution

SEM allows a resolution of the order of 1 to 10 nm , which makes it suitable for examining the surfaces and morphologies of samples. However, this resolution is generally lower than that of TEM.

TEM , on the other hand, offers much higher resolutions, in the range of to 0.3 nm direct visualization of the internal structures of samples. This ability to observe individual atoms and the arrangement of atoms in materials makes TEM the preferred tool for studying atomic-scale materials and biological structures .

Applications

SEM is widely used for material surface analysis in many fields such as materials science, electronics, biology, and nanotechnology. Thanks to its scanning approach, SEM is particularly suitable for observing sample topography and identifying surface defects, such as microcracks or inclusions. It is used for applications such as semiconductor quality control, nanostructure analysis, or composite material characterization.

TEM is primarily used to observe the internal structure of samples. It is commonly used for the analysis of biological membranes, crystallography of materials, and the study of crystal dislocations. For example, it allows for the detailed study of biological systems at the nanoscale, which is crucial in medical research to understand cellular pathologies and interactions at the molecular level.

Type of samples

SEM samples can be relatively thick (up to several millimeters) and typically require only cleaning and polishing to obtain quality images. However, samples must be conductive or must be metallized to prevent the accumulation of electrical charges during analysis.

TEM samples, on the other hand, must be extremely thin (less than 100 nm) and often enhanced by a metal fixation or coating process to prevent degradation during high vacuum examination. Due to the need for low thickness, TEM samples are often more delicate and require specific treatment before analysis.

Cost and accessibility

Due to its higher resolution and the need to prepare more complex samples, TEM is generally more expensive and difficult to access than SEM . In addition, TEM requires vacuum conditions and specialized equipment, which increases the overall cost of the analysis.

In comparison, SEM is often more accessible and faster to use for surface analysis, with relatively lower equipment and maintenance costs. This makes it a more widespread tool in industrial and commercial environments for quality control and material surface analysis.

In summary, although SEM and TEM are based on the same electron microscopy principle, their applications, resolutions, and sample preparations vary considerably, making them complementary in many analytical situations. SEM is ideal for studying surfaces and topography , while TEM excels at observing internal structures at an atomic scale.

Advantages of the Scanning Electron Microscope (SEM)

The scanning electron microscope (SEM) is an essential characterization instrument in many industrial and research fields. With its ability to provide high-resolution images of sample surfaces, it offers significant advantages for a diverse range of applications. This section explores the key benefits of SEM, highlighting its performance, versatility, and effectiveness in meeting complex analytical needs.

High resolution and 3D viewing capability

One of the main advantages of SEM is its ability to obtain images with a resolution ranging from 1 nm to 10 nm, depending on the type of SEM used. This ability to observe fine details on the surface of materials makes it valuable for the analysis of microscopic structures, such as nanostructures , metal grains , or the surface properties of materials .

Furthermore, thanks to its surface scanning operation, the SEM allows for the generation of three-dimensional images. Unlike traditional optical microscopes that produce flat images, the SEM offers a natural relief effect of surfaces, allowing the topography of samples to be visualized with great precision. This is particularly useful for detailed surface analyses in fields such as metallurgy, petrography, or the study of composite materials.

Analysis of the chemical composition of materials

In addition to its ability to visualize surface structures, the SEM is also equipped with detectors capable of performing chemical analysis of materials. One of the most widely used tools is energy dispersive X-ray spectrometry (EDX) , which allows the chemical composition of samples to be characterized by identifying the elements present on the observed surface.

EDS analysis , SEM can provide information about the chemical elements on the surface of the sample, which is particularly useful for identifying contaminants, inclusions , or foreign particles present in materials. These analyses are commonly used in sectors such as microelectronics , semiconductors , and materials quality control , where it is crucial to understand the composition of materials at the microscopic level.

Versatility in analyzing different types of samples

The SEM is extremely versatile in the types of samples it can analyze. Unlike other microscopy instruments, the SEM can be used to examine samples of various shapes and sizes , including insulating or biological samples .

Insulating materials, such as plastics or polymer composites, which can pose problems for observation under an optical microscope, can be analyzed by SEM by metallizing them with a thin layer of gold or carbon, which reduces the static charge and provides a quality image.

Biological samples, which often present challenges due to their fragility or humidity, can also be analyzed using specific preparation techniques. This allows biological structures, such as cells, tissues, or organelles, to be observed while preserving their integrity. SEM is used for detailed studies in fields such as cell biology, medicine, and pharmaceutical sciences.

Ease of use and speed of analysis

Another important advantage of SEM is its ease of use compared to other electron microscopy techniques, such as TEM. Although the operator must be trained to understand the basic principles of the instrument and analysis, the SEM analysis process is relatively fast and intuitive. The automatic scanning allows operators to focus on image interpretation, which significantly speeds up the analysis process.

In addition, image processing and data analysis software associated with SEM facilitates the interpretation of results, allowing rapid analysis and quantification of sample characteristics, such as particle size, chemical element distribution surface area assessment . This helps reduce analysis cycle time, which is a key advantage in industrial production environments where speed of intervention is paramount.

Applications in quality control and industrial inspection

Thanks to its high resolution and its ability to analyze surface topography SEM is a tool of choice for quality control and industrial inspection . For example, in the microelectronics industry, SEM is used to examine integrated circuits, silicon wafers, and conductive materials, in order to detect defects such as cracks, inclusions, or contamination. SEM can also visualize the adhesion of thin films and verify their uniformity, which is essential in fields such as semiconductor manufacturing and flat panel display manufacturing.

In other industrial sectors such as automotive and aerospace, SEM is also used for the analysis of composite materials, metals and electronic components to ensure their compliance with specifications and safety.

Materials failure and expertise testing

SEM a valuable tool in analyzing failures and material problems. For example, when a component exhibits cracks, deformations, or adhesion problems, SEM can observe micro-failures and identify material degradation mechanisms. Fracture analysis in metallic or composite materials, for example, is made possible by SEM's ability to reveal fine details of fracture edges and inclusions that may have contributed to the failure.

This helps optimize product durability, reduce the risk of failure and ensure material safety in critical applications, particularly in the aerospace industry and the manufacturing of high-performance equipment.

Advanced analysis methods associated with SEM

Scanning electron microscopes (SEMs) are not limited to providing surface images. With complementary equipment and advanced analytical techniques, SEMs can provide detailed information on the composition, structure, and properties of materials at a microscopic level. In this section, we explore the advanced analytical methods commonly used with SEMs to enhance the results obtained.

X-ray spectroscopy (EDX/EDS) analysis

One of the most common methods associated with SEM is energy dispersive X-ray spectroscopy (EDX or EDS) . This technique allows the determination of the elemental chemical composition of the sample surface. When an electron beam hits the sample, electrons from the inner shell of atoms are ejected. This excitation produces characteristic X-rays, the energy of which depends on the chemical element. By analyzing the X-ray spectrum, it is possible to quantify the presence of different elements in the sample, even at a nanometric scale.

- Applications : This method is ideal for the qualitative and quantitative of materials, allowing the study of chemical components of metallic, mineral, biological or composite surfaces. It is commonly used in the semiconductor industry , metallurgy , and petrography .

Electron backscattered diffraction (EBSD)

Electron backscatter diffraction (EBSD) is a technique used to obtain crystallographic information about materials. When an electron beam strikes a crystal, it is diffracted by the crystal planes and produces patterns that can be captured by a detector. These patterns can be used to determine the crystal orientation of the material's grains and provide information about the microstructure .

- Applications : EBSD is widely used in the fields of metallurgy, nanostructured materials, and geology. It allows the study of crystal texture, grain orientation, and crystal deformation in materials. This method is essential for researchers in materials science and in industrial applications requiring precise control of the properties of alloys and other materials.

Spot probe microscopy (STEM)

Stem-based probe microscopy (STEM) is an advanced method associated with SEM that combines the surface-examination capability of SEM with the resolution of the transmission electron microscope . This mode allows observation of both the surface and the interior of samples using a very finely focused electron beam.

- Applications : STEM is particularly useful for studies of nanomedicine, nanotubes, and nanoparticles. It is commonly used in research in cell biology, advanced materials, and for the analysis of composites at the atomic scale.

Electron Microprobe (EPMA)

microscopy (EPMA) is a technique associated with SEM that allows the analysis of chemical elements at nanometric resolutions while performing quantitative and spatial . Unlike EDS, which analyzes the surface of the sample, EPMA allows information on the distribution of elements over a greater depth of the sample to be obtained.

- Applications : EPMA is used for detailed chemical analyses, particularly in the fields of geochemistry, mineralogy, and metallic materials. It is also commonly used to characterize inclusions in metals or pollution in materials.

3D imaging and topographic reconstruction

Modern SEMs, thanks to 3D reconstruction , allow detailed images of the sample surface from different angles to be obtained. This technique is based on the acquisition of several 2D images, which are then processed to reconstruct a three-dimensional image of the surface.

- Applications : 3D imaging is used to visualize complex structures on the surface of materials, such as composite textures, powders, and biological structures. It is used in materials analysis and cell biology to observe the shape, topography, and interactions between different structures at the nanoscale.

Use cases in industry and research

SEM is a powerful technique widely used in many industrial sectors and in academic research to solve complex problems related to materials, biology, and physics. This section explores the main applications of SEM in industry and scientific research.

Microelectronics and Semiconductors

semiconductor industry is one of the main users of scanning electron microscopy. SEM is used to inspect and analyze microcircuits and electronic devices , engineers can identify defects , cracks , or contamination at the nanometer level.

- Applications : Inspection of silicon grains, search for defects in conductive materials and characterization of nano-components in the manufacture of electronic chips.

Biology and Biomedical Research

SEM is an essential tool in biology and biomedical research . It allows the study of biological structures , cells , and even viruses at a nanometric scale. SEM is often coupled with techniques such as EDX to determine the chemical composition of biological tissues and cellular structures.

- Applications : The study of the morphology of animal and plant cells, the analysis of pathologies such as viral infections, or the observation of nanoparticles in drug treatments.

Materials and metallurgy

In the field of metallurgy and materials science , SEM is used to study the microstructure of materials, evaluate mechanical properties and analyze failures of metal products. SEM allows the observation of fractures , inclusions or surface defects that affect the performance of materials.

- Applications : Analysis of metal alloys, thin layers, protective coatings, or the study of residues in metals.

Geology and petrography

SEM is a powerful tool for the study of petrography and geology . It is used to analyze rock and mineral to determine their composition and structure . Geologists use SEM to identify minerals , grain boundaries , and crystalline phases in rocks and soils.

- Applications : Study rocks and minerals, analyze sediments and geological particles, and understand the formation of ores.

Food industry

In the food , SEM is used to examine the surface textures of food materials , as well as to analyze contaminant particles or food additives . SEM also plays a role in packaging compliance and in the analysis of chemical compounds present in food products.

- Applications : Quality control of food ingredients, analysis of packaging materials and identification of chemical contaminants.

The scanning electron microscope is therefore an extremely versatile technology and essential to many industries, offering analytical capabilities essential for understanding and optimizing products and materials at a nanometric scale.