DMA analysis is an advanced technique that optimizes the performance of materials by precisely characterizing their viscoelastic properties. Used to study polymers, composites, or elastomers, it highlights the behavior of a material subjected to mechanical stress depending on temperature, frequency, and time. From glass transition to damping, DMA analysis helps define the limits of use of a material and adjust its formulation or transformation process. It is an essential tool in research, development, and quality control.

Table of Contents

What is Dynamic Mechanical Analysis (DMA)?

An advanced thermal analysis technique

Dynamic mechanical analysis, or DMA , is a thermal analysis technique used to evaluate the mechanical properties of a viscoelastic material when it is subjected to oscillatory deformation. Unlike a conventional static test (tension or compression), DMA measures the response of a material to dynamic stress at varying frequency and temperature.

The principle consists of applying a periodic stress – typically a sinusoidal wave – to a sample, and recording its deformation in return. This mechanical response is analyzed as a function of time and the phase shift between the applied force and the measured deformation, which makes it possible to characterize the elastic and viscous parts of the material.

Understanding Viscoelasticity

Polymer, elastomer, or composite materials exhibit mechanical behavior that is intermediate between that of perfectly elastic solids and perfectly viscous fluids. This behavior is called viscoelastic. It depends on numerous parameters such as temperature, time, frequency of stress, and the molecular structure of the material (degree of crosslinking, molar mass, crystallinity, etc.).

DMA allows this response to be precisely quantified through different parameters:

- Storage modulus (E') : measures the elastic rigidity of the material (capacity to store mechanical energy);

- Loss modulus (E'') : measures the viscous component (capacity to dissipate energy in the form of heat);

- Tan delta (tan δ = E'' / E') : ratio between the two modules, also called damping factor;

- Complex modulus (E) : vector combination of the moduli E' and E'', expressed in complex form.

The shape of the curves obtained during a DMA test (E', E'', tan δ as a function of temperature or frequency) makes it possible to identify key areas such as the glass transition, the rubbery zone or the fluid zone of a material.

A method complementary to other techniques

Dynamic mechanical analysis is part of the family of thermal analysis methods, alongside DSC (differential scanning calorimetry), TGA ( thermogravimetric analysis ) and TMA (thermomechanical analysis). Unlike these techniques, DMA does not directly measure the variation in mass or heat but rather the mechanical response of the material.

It is more sensitive than DSC for detecting the glass transition temperature (Tg), particularly in the case of highly filled, crosslinked or composite materials. It also allows the detection of secondary transitions (β, γ), invisible with other methods.

In the laboratory, DMA is often used in addition to other analyses to obtain a complete view of the behavior of a material:

- DSC for glass transition and melting temperatures;

- TGA for thermal stability and decomposition;

- TMA for coefficients of thermal expansion and deformations under constant load.

This complementarity allows for in-depth thermal and mechanical characterization, essential in the plastics, cosmetics, packaging and health sectors.

How does a DMA analysis work?

The physical principle of dynamic deformation

DMA analysis is based on a fundamental principle: the application of a periodic to a material, generally in the form of a sinusoidal wave , and the measurement of the resulting deformation . This dynamic stress allows the observation of the material's response in terms of stiffness, damping capacity and viscoelastic behavior, under controlled conditions of temperature , frequency , amplitude and time .

When a material is subjected to this oscillatory stress, the deformation it undergoes is not perfectly in phase with the applied force. We observe a time lag , called phase shift (δ) . This phase shift is directly linked to the viscous of the material's behavior: the more the material dissipates energy (in the form of heat), the greater the phase shift.

This phase shift makes it possible to break down the mechanical response of the material into two components:

- elastic component (in phase with the stress) represented by the storage modulus E' ;

- viscous component (in phase quadrature) represented by the loss modulus E'' .

The vector sum of these two components gives the complex modulus E *:

E *= E' +i E''

The ratio E''/E' gives the loss factor or tan δ , an essential indicator of the material's ability to dampen vibrations. This quantity is particularly valuable in the automotive or electronics sectors, where reducing vibrations and noise is a performance issue.

Parameters monitored during a DMA test

The richness of DMA analysis lies in its ability to vary several parameters in a precise and controlled manner:

- Temperature : The sample is placed in a thermostatically controlled enclosure that can cover a wide range, generally from −150 °C to +600 °C depending on the equipment. This variation makes it possible to detect phase transitions (Tg, Tm) and to study mechanical behavior when hot or cold.

- Frequency : This corresponds to the speed at which the stress is applied. It can vary from a few millihertz to several hundred hertz. Frequency analysis makes it possible to simulate various dynamic stress conditions (slow or fast vibrations).

- Amplitude / strain : The amplitude of the applied stress must remain within the linear of the material for the results to be usable. If the amplitude is too high, the behavior may become nonlinear, making the modulus calculations invalid.

- Time / isothermal or scanning mode : The test can be carried out at constant temperature (isothermal mode) or continuously variable (ramp mode), with typical heating rates of 1 to 10 °C/min. Some tests extend over several hours to monitor the evolution of mechanical properties over the long term.

Modern instruments also allow double sweeps , combining frequency and temperature variation, in order to construct master curves representing the behaviour of a material over a very wide range of stresses.

The different methods of solicitation

The sample is fixed on a sample holder adapted to its shape and nature, then subjected to a precise stress mode, depending on the property that one wishes to study:

- Tension-compression : used for solid materials such as rigid polymers, composites or certain elastomers. This mode provides access to the dynamic Young's modulus (E*).

- Bending : commonly used for films, filled polymers or thermosets. The three-point bending can simulate stresses close to those encountered in real use (beams, shells, etc.).

- Shear : often applied to pasty, viscous or liquid materials (e.g. glues, varnishes, inks). It allows the determination of the shear modulus G * and the dynamic viscosity η *.

Each type of deformation requires a sample geometry . For example, for a tensile test, the sample must be slender (parallelepiped or cylindrical type), while a shear test will be carried out on a shorter and more massive sample, often in a dedicated cell.

The DMA device automatically calculates the viscoelastic moduli from the measured force and the imposed deformation , taking into account the exact geometry of the sample.

Common Test Methodologies and Protocols

Several types of DMA tests are performed depending on the objective:

- Thermal scanning : measurement of mechanical properties as a function of temperature, to detect transitions (glassy, rubbery, fluid). This is one of the most common tests in the laboratory.

- Frequency sweep : Useful for simulating vibration or cyclic loading conditions. Allows the construction of predictive models of vibration or damping behavior.

- Creep testing : Application of a constant stress and measurement of deformation over time. Represents the ability of the material to deform slowly under continuous load.

- Stress relaxation tests : measurement of the progressive decrease in stress in a material at constant deformation. Allows long-term behavior .

- Dynamic fatigue tests : replication of stress cycles over long periods to identify mechanical limits before failure or loss of performance.

Each test is programmed via control software (e.g. Dynatest), which automatically manages temperature ramps, stages, frequencies and data recording.

Depending on requirements, a DMA test can last from a few minutes (simple isothermal test) to several hours (slow thermal scan with stabilized stage). The results are then used in the form of curves, tables or mathematical models, according to the standards in force (ISO 6721, ASTM D4065, etc.).

All of these parameters make DMA a highly versatile , capable of reproducing a wide variety of mechanical and thermal stresses, while providing precise and reproducible data on the durability and performance of materials.

Are you looking for an analysis?

What materials can be analyzed by DMA?

A method suitable for many polymer materials

One of the major advantages of dynamic mechanical analysis is its ability to be applied to a wide variety of materials, particularly in the field of polymers. Thanks to its multiple stress modes (tension, bending, shear), DMA can be used to test solid materials as well as flexible films, foams, adhesives, and semi-liquid products.

The main materials targeted are:

- Thermoplastic polymers : Often used in packaging, electronics, and automotive applications, they exhibit mechanical behavior that is highly temperature-dependent. DMA can be used to characterize their rigidity, elasticity, and vibration resistance across a wide range of conditions. Examples: polypropylene, polycarbonate, PET.

- Thermosetting polymers : such as epoxy, polyurethane, or phenolic resins. These materials are irreversibly crosslinked and have stable thermomechanical properties. DMA analysis is used to assess their glass transition temperature (Tg), fatigue resistance, and the impact of post-curing.

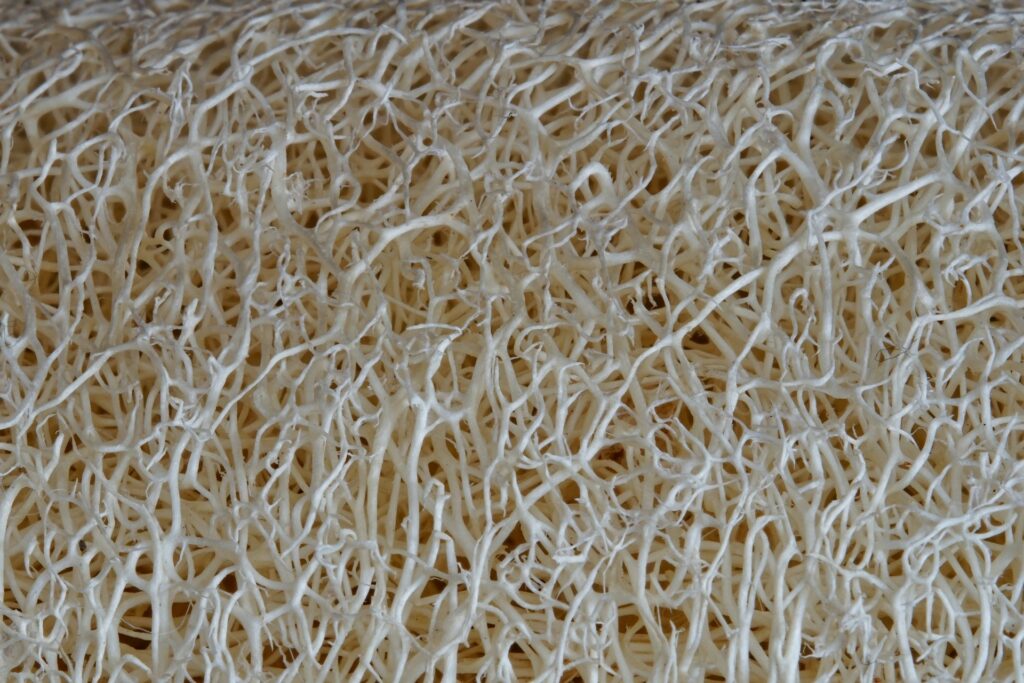

- Elastomers : highly deformable materials such as natural rubber, silicone, or styrene-butadiene copolymers. DMA is essential for analyzing their flexural or shear behavior, including their damping factor (tan δ), their cold stiffness, or their dynamic behavior at high frequencies.

- Polymer matrix composites : these materials reinforced by fibers (glass, carbon, flax) are studied in DMA to evaluate their mechanical resistance in bending, their fatigue behavior, and their anisotropy (influence of the orientation of the fibers on performance).

- Films and fibers : Whether food films, textile fibers, or medical devices, DMA can be used to test their tensile strength, flexibility, and thermal stability. These thin materials require precise testing conditions (small samples, low deformation amplitudes).

- Solid pharmaceutical materials : In the case of tablets or capsules, DMA analysis can be used to verify mechanical stability and changes in viscoelastic properties as a function of temperature and humidity. These tests are useful for packaging and storage.

Specific materials and special cases

In addition to conventional materials, DMA can be used to test more complex samples or those from constrained environments:

- Polymers for medical devices : prostheses, implants, catheters, etc. These products require high mechanical stability and biocompatibility. DMA helps predict their behavior under physiological conditions (37°C, high humidity, prolonged mechanical stress).

- Bio-sourced or recycled materials : PLA, PHA, natural fibers (flax, hemp), recycled elastomers, etc. These materials often exhibit significant variability related to their origin or manufacturing process. DMA analysis allows their performance, thermal transition, and lifespan to be assessed.

- Multi-layer composite materials : used in flexible packaging, membranes or technical textiles, they require detailed characterization of interfaces and energy dissipation.

- Technical adhesives and glues : Widely used in aeronautics, automotive, and electronics, adhesives must ensure mechanical strength, controlled flexibility, and good aging stability. DMA allows their curing to be monitored, their damping capacity to be analyzed, and their shear modulus to be determined.

- Materials in extreme conditions : some DMA tests can be carried out at very low (−150°C) or very high (+600°C) temperatures, making it possible to simulate real-life usage conditions in the aerospace, nuclear or industrial equipment sectors.

Concrete industrial applications

DMA analysis is used in many sectors to support the development of new materials, control production quality, or understand the causes of failure. Here are some examples of concrete applications:

- Automotive : assessment of the durability of seals, silent blocks, or dashboard elements subject to vibration. Study of the thermal behavior of interior materials exposed to solar radiation.

- Aeronautics : characterization of structural composites, optimization of the weight/rigidity ratio, prediction of aging under thermal cycles.

- Packaging : testing of film flexibility, mechanical resistance of trays, thermal resistance of multi-layer materials.

- Cosmetics : analysis of polymers present in packaging or textures, study of the dimensional stability of bottles under mechanical stress.

- Electronics : validation of polymers for flexible printed circuits, analysis of component fixing adhesives, prediction of viscoelastic behavior under heating.

- Food industry : testing of damping in insulation or cushioning materials, evaluation of the thermal stability of coatings or packaging in contact with foodstuffs.

In all these cases, DMA provides precise , quantifiable and reproducible , allowing manufacturers to make informed decisions regarding formulation, material selection or market launch strategy.

What is a DMA analysis used for?

Determine the glass transition temperature (Tg)

One of the first applications of DMA is the determination of the glass transition temperature (Tg) of a polymer material. This temperature corresponds to a critical threshold beyond which a polymer changes from a rigid, glassy state to a more flexible, rubbery state. It is essential for defining the field of use of a material.

In a DMA test, this transition is detected by analyzing the tan δ versus temperature . The tan δ peak usually indicates the glass transition temperature. Unlike other techniques such as DSC, DMA is able to detect this transition with very high sensitivity, even in highly filled, crosslinked or composite materials.

Tg is a key parameter in many sectors:

- In packaging: to guarantee the mechanical strength of trays or films when hot.

- In cosmetics: to ensure the stability of bottles or formulation materials.

- In aeronautics: to check the performance of composites subjected to significant thermal variations.

Study the rigidity and elasticity of materials

DMA analysis provides detailed information on the mechanical stiffness of a material, particularly through the storage modulus (E') , which reflects its ability to resist elastic deformation. This modulus is measured in different thermal regimes to monitor the evolution of the material's stiffness during heating.

The curves obtained allow us to visualize several characteristic zones:

- Glassy zone : the material is rigid (high E'), generally brittle.

- Transition zone : the modulus drops rapidly, the material becomes viscoelastic.

- Rubbery zone : the material regains elastic behavior but with a much lower modulus.

DMA thus makes it possible to compare different formulations, to evaluate the effect of heat treatment, aging, or the presence of additives (plasticizers, fillers, crosslinkers).

It is also used to calculate the dynamic Young's modulus (E) * and, in some cases, Poisson's ratio , by combining the tensile and shear results.

Analyze the vibration damping capacity (tan δ)

The loss factor (tan δ) is a major indicator of the damping behavior of a material. It measures the material's ability to dissipate mechanical energy (vibrations, shocks, deformations) in the form of heat, through internal friction.

A high tan δ means that the material absorbs vibrations well (good damper), while a low tan δ indicates a more rigid and less dissipative behavior (like a metal).

This property is crucial in:

- The automotive industry (silent blocks, dashboards, seals),

- The building (vibration insulation),

- Electronic equipment (supports, fixings, sheaths),

- Sports (soles, snowshoe or ski materials).

DMA analysis allows us to identify the temperature and frequency ranges where tan δ is maximum, i.e. where the material offers its best damping performance.

Understanding the long-term behavior of materials

isothermal mode tests , such as:

- Creep : application of a constant load and measurement of deformation over time .

- Stress relaxation : maintaining a constant deformation and measuring the reduction in force required.

- Dynamic fatigue tests : repeated stress cycles to simulate prolonged usage conditions.

These tests make it possible to predict the behavior of the material over the long term , in conditions close to reality: thermal cycles, repeated stresses, accelerated aging.

For example :

- A prosthesis polymer must retain its flexibility after several years of use.

- A structural adhesive must not lose its adhesion after prolonged exposure to heat.

- A composite engine cover material must withstand heating/cooling cycles without cracking.

These tests are essential for product validation , life simulation or compliance with industrial standards .

Facilitate the selection and formulation of materials

DMA is a strategic tool for R&D teams , formulators and materials engineers . Thanks to the precise mechanical data it provides, it is possible to:

- Compare several raw materials or formulations,

- Choose the most suitable material for a given application (rigid, flexible, shock-absorbing, etc.),

- Optimize a manufacturing process (post-curing, extrusion, molding, etc.),

- Adjust the level of plasticizer, filler or crosslinker in a formulation.

It is also an excellent tool for analyzing the effects of a defect : modification of the modulus, drop in Tg, loss of elasticity, etc. DMA analysis makes it possible to identify non-conformity or premature aging, with a view to correcting the formulation or the process.

How to interpret the results of a DMA analysis?

Reading DMA curves: modules and loss factor

The results of a DMA analysis are often presented in the form of curves representing the different parameters measured during the test: storage modulus (E') , loss modulus (E'') , tan δ and complex modulus (E) * as a function of temperature or frequency. These curves provide a complete view of the mechanical behavior of the material and allow several key points to be identified.

Storage module (E')

The storage modulus (E') is a measure of the elastic stiffness of the material. It indicates the material's ability to store applied mechanical energy. In an E' curve as a function of temperature, we can observe:

- An increase in rigidity in the vitreous zone (rigid material),

- A decrease in stiffness in the transition zone (change of state of the material),

- Stabilization of rigidity in the rubbery area (flexible material).

The position of the glass transition temperature (Tg) can be easily identified by the marked drop in the storage modulus.

Loss modulus (E'')

The loss modulus (E'') quantifies the viscous part of the material, i.e. the ability to dissipate energy in the form of heat. The more energy a material dissipates, the higher the loss modulus. During a DMA analysis, this curve shows:

- A loss peak associated with the glass transition temperature (Tg), where the material changes from a rigid to a more flexible state.

- A reduction in the loss modulus in the rubbery zone, as the material becomes more flexible.

The intensity of this peak can also indicate the damping of the material, a characteristic sought after in many industrial sectors such as automotive or electronics.

Tan δ (loss factor)

The loss factor (tan δ) is the ratio of the loss modulus to the storage modulus (E'' / E'). This value is a key indicator of the material's damping behavior. A high tan δ means that the material dissipates a large amount of energy (e.g., a shock absorber), while a low tan δ indicates a stiffer and more elastic material.

- In the glassy zone, tan δ is small because energy dissipation is low.

- In the transition zone, tan δ increases considerably, reaching its maximum around Tg.

- In the rubbery zone, tan δ remains high, but the energy dissipation is more stable, meaning that the material is more flexible but less dissipative.

Complex module (E*)

The complex modulus (E) * is the vector combination of the storage modulus and the loss modulus. It represents the overall response of the material to dynamic loading, integrating both its capacity to store energy and to dissipate it. Depending on temperature or frequency, this curve can provide information on the transition between stiffness and flexibility , the glass transition , and the dynamic response of the material under different conditions.

Analysis of transition temperatures and behavior zones

One of the major advantages of DMA is the ability to accurately detect transition temperatures . These transitions mark significant changes in the material's mechanical properties, which are crucial for its use in real-world applications.

Glass transition temperature (Tg)

Tg is a critical temperature, especially for polymers and elastomers. It represents the temperature at which a polymer changes from its glassy (rigid and brittle) state to a more flexible and rubbery state. This temperature is directly related to the thermal and mechanical resistance properties of a material . DMA curves allow this temperature to be precisely located, often associated with a peak in the tan δ curve.

Thermoplastic materials, such as polycarbonate or polymethylmethacrylate (PMMA) , have relatively high Tgs, while elastomers such as natural rubber have a much lower Tg. This data is crucial in determining the conditions of use of the material.

Rubber transition temperature (Tc)

The rubber transition (Tc) refers to the point at which a material, after changing from a glassy to a rubbery state, enters into reversible elastic behavior . This temperature is important for elastomers and polymers used in applications such as gaskets, tires, or shock absorbers. It can be determined by analyzing the tan δ curve, which shows a marked increase in damping capacity.

Interpretation of results according to the application

The results obtained by DMA must be interpreted according to the specific requirements of each sector. Depending on the performance needs , the material selection criteria may vary.

In the automotive industry

For the automotive industry, for example, mufflers , tires , and seals are subject to vibration and thermal stresses. DMA analysis can be used to test damping capacity (tan δ), determine thermal stability , and ensure material durability under temperature changes. The results should show good damping in the operating temperature ranges of vehicles.

In electronics

In the electronics industry, materials used for flexible components or encapsulants must be able to withstand mechanical stress while maintaining their thermal integrity . DMA verifies that these materials have a glass transition (Tg) high enough to avoid deformation under high operating temperatures.

In food packaging

DMA analysis of packaging materials ensures that plastic films or food packaging components withstand temperature variations and maintain their mechanical properties throughout the product life cycle. Migration and thermal stability are crucial to ensure food safety.

Precautions and good interpretation practices

When interpreting DMA results, it is essential to consider several external factors :

- Sample preparation : Samples must be prepared uniformly and correctly sized for each type of test (tensile, bending, shear).

- Test conditions : Temperature, humidity, and material pretreatment (e.g., aging or UV exposure) may influence results.

- Comparability of results : Comparing the results obtained with those of reference materials or industrial standards allows the data to be validated and ensures their relevance for the target application.

By following these best practices, the data obtained via DMA not only allows us to control the quality of materials but also to guide the research and development of new products.

Why choose DMA analysis for your materials testing?

The benefits of DMA analysis for polymer materials

Complete characterization of mechanical properties

DMA allows for detailed and precise characterization of the and viscous properties of polymers. Unlike other techniques, DMA simultaneously measures several essential parameters, including storage modulus (elastic stiffness), loss modulus (energy dissipation), and loss factor (tan δ) , thus enabling in-depth analysis of dynamic mechanical behavior . This characterization is crucial for optimizing materials for specific applications, such as gaskets, packaging materials, or automotive components.

Detection of critical thermal transitions

One of the major applications of DMA is the detection of glass transition temperatures (Tg) , which is fundamental for assessing the thermal stability of polymers. The ability to accurately determine this temperature allows for a better understanding of how a material reacts under different temperature conditions, which is particularly important for applications subject to thermal variations (tires, automotive parts, packaging materials).

Monitoring aging and durability

DMA is also used to simulate the aging of materials, allowing their long-term durability Stress relaxation and creep tests performed in isothermal mode are essential for predicting the behavior of materials under prolonged use conditions. This allows manufacturers to anticipate potential failures and improve material formulations to ensure their longevity.

A reliable and flexible method for diverse sectors

One of the main advantages of DMA is its flexibility in application to a wide range of materials and in a wide variety of sectors. Here are some examples of areas where DMA plays a key role:

Automotive and Aerospace

In the automotive and aerospace , DMA is used to test materials under extreme temperature and vibration . It validates the performance of composites used in structures, tests the resistance of seals to thermal and mechanical variations, and ensures the stability of interior materials in vehicles or aircraft.

Packaging and food safety

In the food , DMA is used to test plastic films , barriers Migration and thermal stability tests ensure that the materials used do not affect product quality and comply with safety standards, such as EC Regulation No. 1935/2004.

Medical and pharmaceutical devices

DMA analysis is also crucial in the field of medical devices and pharmaceutical materials , where biocompatibility and mechanical stability are paramount. Materials used for implants, prosthetics, and drug delivery devices must be tested for their long-term strength and stability under mechanical and thermal stresses .

Electronics and sensitive equipment

In the electronics , DMA is used to test the stiffness and flexibility of flexible components such as flexible printed circuits . These materials must ensure reliable performance under different temperature and mechanical stress conditions.

The reliability and accuracy of the results obtained

Another major strength of DMA analysis is the reliability of the results it provides. The use of state-of-the-art equipment viscoanalysis devices (e.g., VA2000 from METRAVIB RDS), allows tests to be carried out with exceptional precision , even on materials with complex behaviors .

Quality standards and compliance

Accredited laboratories that use DMA, such as those certified to ISO 17025 and COFRAC , ensure that tests are carried out according to current international standards quality , safety and performance required by industries. This is particularly important for highly regulated sectors, such as food, pharmaceuticals and aeronautics.

Repeatability and reproducibility of tests

Through standardized test protocols , DMA provides repeatability and reproducibility of results, allowing manufacturers to track changes in material properties over time and validate changes to the formulation or manufacturing process.

A strategic choice for R&D and product optimization

Using DMA in laboratories allows companies to conduct research and development , quickly assessing the and mechanical properties of materials before they are put into production. This helps optimize manufacturing processes , reduce validation testing costs consistent quality throughout production.

Acceleration of the development cycle

DMA analysis helps reduce time to market by providing reliable, actionable data for new product development. By fine-tuning material formulations and evaluating their behavior before production, companies can improve process efficiency while meeting performance requirements.

Optimization of material performance

By adjusting parameters such as chemical composition , additives or crosslinking , DMA helps manufacturers achieve the optimal mechanical properties for each specific application. This ensures that materials meet technical requirements , but also environmental standards .