Tensile testing is a crucial method for characterizing the mechanical properties of materials in various industrial sectors, from research to production. By measuring how a material reacts to a progressive tensile force, these tests allow the determination of essential characteristics such as yield strength, tensile strength, and elongation at break.

This article will guide you in understanding tensile testing, its importance in material selection and quality verification, and laboratory analysis procedures, taking into account ISO and ASTM standards.

1. What is a tensile test? Definition and basic principles

1.1 Definition of a tensile test

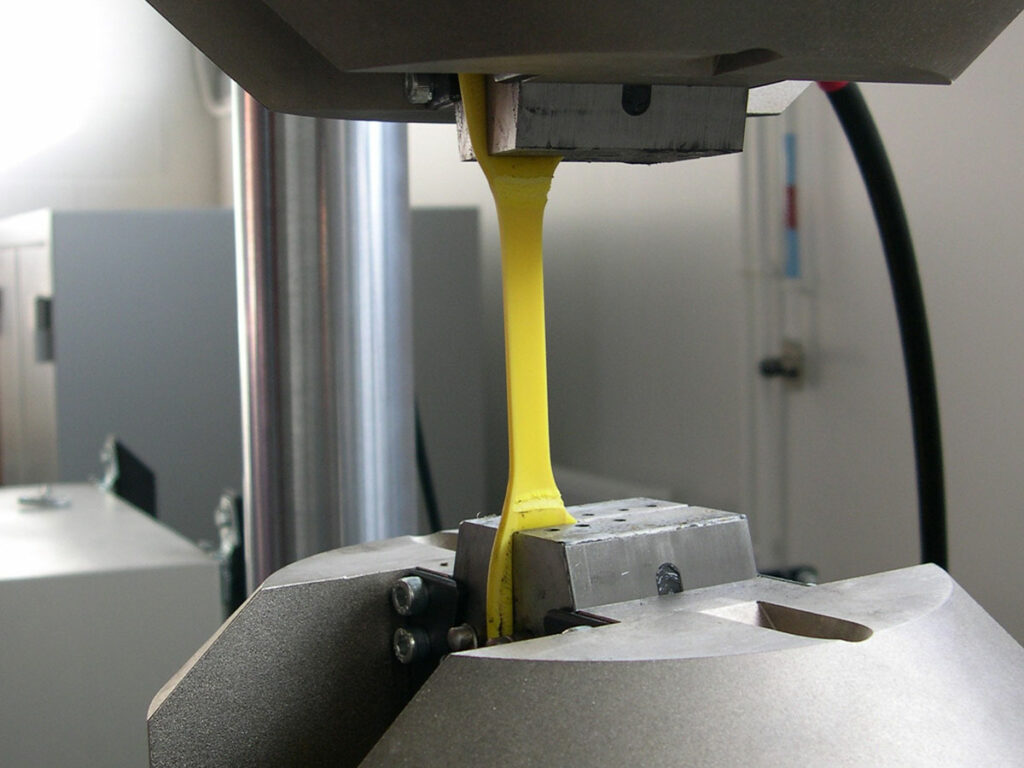

The tensile test is a standardized mechanical test used to measure the strength and behavior of a material when stretched to the point of failure. This test is often performed in a laboratory where a specimen, prepared according to specific standards, is placed in a tensile testing machine. The specimen is subjected to a constant tensile force until it reaches its breaking point, allowing data to be collected on its stress and strain.

1.2 Basic principles of tensile testing

The tensile test is based on fundamental concepts of physics and mechanics. Stress, or the internal resistance of the material, is measured as a function of the deformation caused by the applied force. When a material is stretched, its molecular bonds gradually extend, reaching a limit beyond which it undergoes plastic deformation and then breaks. The stress-strain curve allows visualization of the material's behavior by showing the different phases: elasticity, plasticity, and failure.

2. The parameters measured in a tensile test

2.1 Tensile strength

Tensile strength represents the maximum stress that a material can withstand before breaking. It is expressed in megapascals (MPa) and calculated by dividing the maximum applied force by the initial cross-sectional area of the sample.

2.2 Elastic limit and Young's modulus

The yield strength is the maximum stress a material can withstand without permanent deformation. Young's modulus, or the modulus of elasticity, expresses the material's stiffness by measuring the slope of the tensile curve during the elastic phase. This parameter is crucial for understanding whether a material will return to its original shape after stress is removed.

2.3 Elongation at break and ductility

Elongation at break represents the material's ability to deform before breaking. A high percentage indicates a ductile material, while a low percentage corresponds to brittle, inflexible materials.

2.4 Poisson's ratio

Poisson's ratio is a measure of the transverse decrease relative to the longitudinal elongation of a material under tension. This coefficient is essential for predicting the behavior of a material subjected to uniaxial stresses.

3. Tensile Test Procedures

3.1 Preparation of the test specimen and applicable standards

Tensile tests must be performed on specimens prepared according to standards (ISO 6892 for metals, ASTM D638 for polymers). These specimens are standardized to guarantee reproducible and comparable results, and can be cylindrical or flat depending on the material.

3.2 Test procedure: from sample fixation to rupture

The specimen is placed in a tensile testing machine equipped with jaws that firmly hold its ends. Once the sample is secured, the machine applies a progressive tensile force until it breaks, while simultaneously measuring the applied force and the elongation of the sample.

3.3 Stress-strain curve

The data obtained allows us to plot a stress-strain curve, which shows the different stages of material deformation. This curve provides an overview of the mechanical behavior and properties of the material, from the beginning of elastic deformation to failure.

4. Methods and equipment used for laboratory tensile testing

4.1 Universal traction machines

Tensile tests are generally performed on universal tensile testing machines, designed to apply a controlled force to samples of various materials. These machines can be equipped with force sensors and strain measurement devices for precise analysis.

4.2 Tensile test variants depending on the types of stress

In addition to standard tests, variations may include high-temperature tensile tests, low-temperature tests, or rapid tests to observe deformation under various stress conditions.

4.3 Advanced measurement techniques: spectroscopy, strain measurement, electronic sensors

Some advanced analyses may involve techniques such as spectroscopy or thermal imaging to monitor microscopic changes in the material during testing.

Are you looking for an analysis?

5. Analysis of tensile test results: interpretation and applications

5.1 Data analysis: strength, elasticity, ductility

The data from the test allows us to calculate tensile strength, elongation at break, and yield strength. These characteristics indicate the material's ability to withstand a load before failing and allow us to predict its behavior under different usage conditions.

5.2 Importance of results for quality control and R&D

Industries use tensile test results to validate material quality, ensure compliance with safety standards, and adjust formulations as part of research and development.

6. Tensile tests on various materials

6.1 Tensile tests on metals

Metals often require tensile testing to verify their ability to withstand high loads. These tests help identify properties such as ductility, fatigue resistance, and fracture toughness.

6.2 Tensile tests on polymers

Tensile testing of polymers helps to determine their elasticity and tensile strength, essential parameters for applications in the automotive, packaging, and medical sectors.

6.3 Tensile tests on composite and ceramic materials

Composites, made of reinforced fibers, and ceramics, known for their rigidity, are tested to evaluate their behavior in the presence of mechanical loads in extreme environments.

7. Standards and regulations in tensile testing

7.1 ISO and ASTM standards for tensile testing

ISO standards (such as ISO 6892) and ASTM standards (such as ASTM D638) specify the test methods and quality criteria to be met to ensure the reliability of the results.

7.2 Laboratory certifications and accreditations (ISO 17025, COFRAC)

Accredited laboratories (ISO 17025, COFRAC in France) offer additional guarantees regarding technical competence and the validity of results, necessary for analyses that comply with industry standards.

8. Practical applications and industrial importance of tensile testing

8.1 Tensile testing in the automotive and aeronautical industries

In the automotive and aerospace industries, materials are subject to strict safety requirements, and tensile testing helps to select alloys and materials capable of withstanding extreme mechanical stresses.

8.2 Usefulness for the construction and infrastructure sectors

Construction materials such as concrete and steel are tested in tension to ensure they meet the strength standards required for the durability and safety of structures.

8.3 Applications in the polymers and biomaterials sector

Tensile testing is essential in the manufacture of medical devices and consumer products, as it ensures the reliability of polymer materials and their suitability to performance and durability requirements.

Conclusion

Tensile testing is essential for evaluating the mechanical properties of materials in a wide range of industrial applications. By measuring tensile strength, elasticity, and ductility, it provides crucial data for material design, quality control, and optimization. Adherence to standards and advanced laboratory techniques ensure the validity of the tests, enabling industries to select the most suitable materials and meet performance and safety requirements.