Tensile strength is a fundamental measure of a material's ability to withstand stretching or deformation forces without breaking. It is essential in many areas of engineering and manufacturing because it allows for the evaluation of the durability and quality of materials under stress. The maximum resistance a material can withstand before failing is calculated and expressed in units of stress, typically megapascals (MPa) in the International System of Units (SI).

1. Understanding tensile strength

1.1. Definition and explanation

Tensile strength represents the maximum load a material can withstand per unit area before breaking. This is essential for evaluating materials used in applications where high forces are involved, such as in metal structures, industrial textiles, and polymers.

1.2. Importance of tensile strength in industry

This characteristic is crucial for engineers, as it helps determine if a material is suitable for specific loads. Good tensile strength means the material can withstand forces without breaking, which is fundamental for structural applications where safety is paramount.

2. Calculation of tensile strength

2.1. Basic Formula

Tensile strength is calculated using the following formula:

Tensile strength (Rm) = Maximum force (Fm) / Initial cross-sectional area (S0)

It is expressed in megapascals (MPa) or newtons per square millimeter (N/mm²). For example, if a force of 500 N is applied to a 5 mm² cross-section, the tensile strength will be 100 MPa.

2.2. Stress-strain diagram

In a tensile test, the material's behavior is represented by a stress-strain diagram, allowing the identification of various thresholds such as the yield strength and the breaking point. This diagram helps to understand how the material deforms under stress and where the maximum strength is located.

3. Tensile strength testing techniques

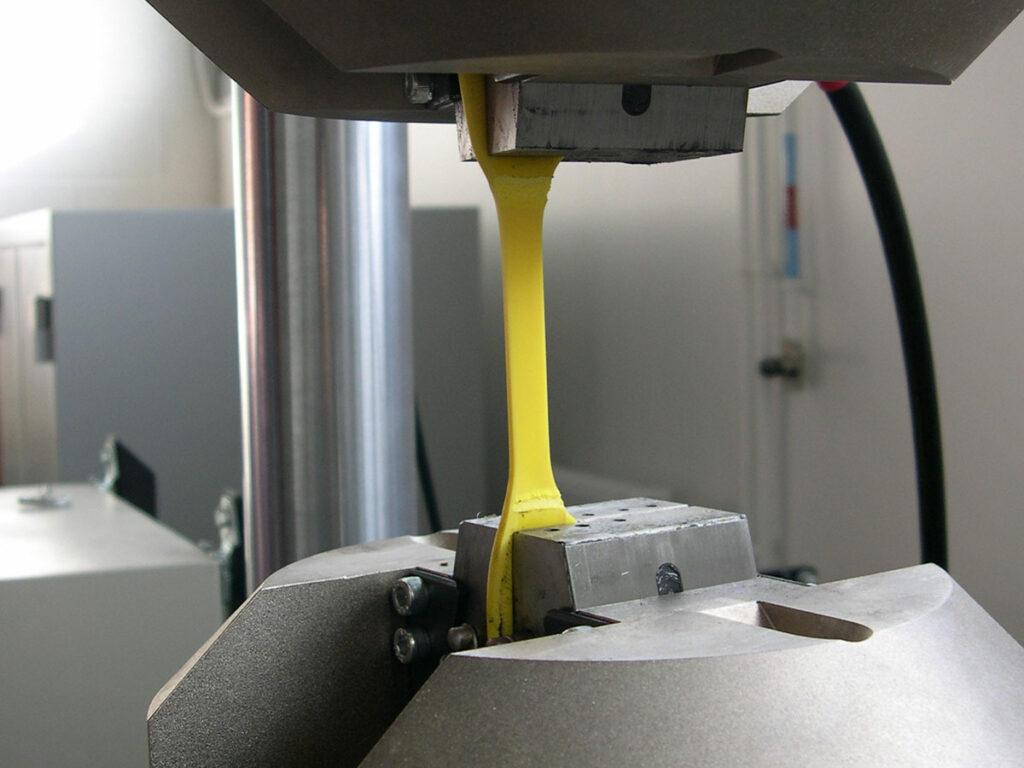

3.1. Standard tensile test

The tensile test involves stretching a specimen until it breaks and measuring the applied force and the resulting elongation of the material. This test is commonly performed on tensile testing machines that control both force and deformation. It allows for the collection of precise data on the material's yield strength, maximum tensile strength, and breaking point.

3.2. Other techniques used

- Tensometry : A technique that uses strain gauges to measure the deformation of the material in real time.

- Ultrasonic evaluation : Used for certain fragile or delicate materials that can break easily.

4. Analysis of common materials and their tensile strength

Some materials have particularly high or low tensile strength depending on their composition and use. Here are a few examples:

| Material | Tensile strength (MPa) |

| Mild steel | 400-550 |

| Aluminum | 95-110 |

| Titanium | 900 |

| Nylon-6 | 45-90 |

| Carbon fiber | Up to 7000 |

This diversity allows engineers to choose materials according to their specific needs, such as lightness, flexibility or strength.

Are you looking for an analysis?

5. Influence of environmental factors

Tensile strength can vary depending on temperature, humidity, and other external factors. For example:

- High temperature : Can weaken certain metals and polymers, reducing their strength.

- Humid conditions : Can affect polymers or composite materials, making them more brittle.

6. Importance of ISO standards for tensile strength testing

Tensile strength tests must be carried out according to strict standards such as ISO 6892 (for metals) and ISO 527 (for plastics). These standards guarantee the reliability of the results and ensure that the materials meet safety criteria in various industrial applications.

7. Applications of tensile strength in industry

7.1. Automotive Industry

In the automotive industry, tensile strength is crucial for parts subjected to constant forces, such as frames and chassis, which must withstand loads without giving way.

7.2. Construction Industry

Construction materials, particularly structural steels, are evaluated for their ability to withstand significant loads without breaking, ensuring the stability of buildings and infrastructure.

8. Laboratory analyses and tensile strength testing

8.1. Analysis Procedures

In laboratories, several analytical methods are used to verify the tensile strength of materials:

- Universal tensile testing machines : Equipped with force sensors to accurately measure tensile forces.

- Thermomechanical analysis (TMA) : Allows verification of the stability of materials under different temperatures.

- Spectroscopy : Analyzes the internal structure of materials to evaluate their resistance based on their constituent elements.

8.2. Importance of standards and certifications

Analyses must comply with standards such as ISO 17025 to ensure the reliability of results. Laboratories accredited by COFRAC provide testing that meets regulations, guaranteeing optimal levels of quality and safety.

Conclusion

Tensile strength is a crucial indicator for determining the durability and safety of materials in numerous industrial applications. Through laboratory analyses and quality standards, engineers can ensure that materials meet the specific requirements of different sectors. In this way, tensile strength continues to play a key role in the development and safety of modern technologies.