Thermal expansion is a fundamental phenomenon in materials science, construction, and physics in general. It is defined as the increase in a material's dimensions when subjected to a rise in temperature, and conversely, its contraction when its temperature falls. This phenomenon has significant implications for the design and use of materials under varying temperature conditions, such as in bridges, buildings, electronic components, and much more.

Understanding the basics of thermal expansion , as well as the coefficient of thermal expansion, is therefore crucial to anticipating the behavior of materials and avoiding potential structural or mechanical problems.

1. What is the coefficient of thermal expansion?

Definition of the coefficient of thermal expansion

The coefficient of thermal expansion is a value that quantifies the extent to which a material expands when exposed to a change in temperature at constant pressure. This coefficient, usually denoted by the Greek letter α, is a precise measure of a material's thermal response and can be used to predict how a material will behave under changing thermal conditions. More specifically, it expresses the change in length or volume per degree Celsius and is often expressed in °C⁻¹ or K⁻¹.

There are two main types of coefficients of expansion:

- The coefficient of linear thermal expansion (αL) : It describes the increase in a linear dimension (e.g., length) of a solid material for a given temperature variation.

- The coefficient of volumetric thermal expansion (αV) : It quantifies the increase in volume of a material for the same temperature change. In the case of an isotropic material, the coefficients of linear and volumetric expansion are related by the simple equation: αV = 3αL.

These coefficients of thermal expansion allow for a better understanding and prediction of the thermal behavior of materials in various applications, particularly for solids and liquids. In general, materials expand predictably with temperature, but this expansion is influenced by the material's internal structure, its state (solid, liquid, gas), and its chemical composition.

The phenomenon of thermal expansion and its origins

Thermal expansion is a physical phenomenon that can be explained by the behavior of a material's atoms and molecules in response to temperature. When a material is heated, its constituent atoms and molecules acquire additional energy, increasing the amplitude of their vibrations around their equilibrium positions. This increased movement causes the atoms to move further apart, resulting in an overall increase in the material's length or volume.

Case of solids : In a solid, atoms are bound by specific interatomic forces that dictate the shape and structure of the material. At low temperatures, the vibrations of the atoms remain confined around their average positions. However, as the temperature increases, these vibrations become asymmetric, causing a progressive separation of the atoms and, consequently, an expansion of the material. This behavior is even more pronounced for materials with more complex interatomic potentials, in which the asymmetry of the vibrations directly influences the magnitude of thermal expansion.

Case of liquids and gases : In liquids, molecules have some freedom of movement, but they are still relatively close to each other compared to gases. Thus, the expansion of liquids is often greater than that of solids because the molecules can easily move apart under the effect of heat. The special case of water between 0 and 4 °C is noteworthy, as it contracts when heated within this range, resulting in a negative coefficient of thermal expansion. For gases, thermal expansion is even more pronounced. As the temperature increases, the molecules acquire more kinetic energy, thus increasing their movement and separation, which translates into an increase in pressure at constant volume or an expansion of volume at constant pressure, as described by the ideal gas law.

Factors influencing thermal expansion : Several factors influence the thermal expansion of a material:

- Nature of the material : Metals generally have higher coefficients of thermal expansion than ceramics or composites due to their more flexible atomic structures.

- Ambient temperature : Thermal expansion coefficients often vary with temperature. Some materials exhibit non-linear dilatometric behavior, particularly at very high temperatures or near their melting point.

- State of matter : Solids, liquids, and gases react differently to temperature changes due to the nature of their bonds and the freedom of movement of their atoms or molecules. Gases, for example, have much higher coefficients of thermal expansion than solids and liquids because of the greater mobility of their particles.

Thermal expansion, while often imperceptible in small samples, can cause significant effects in larger structures or devices, such as bridges, pipelines, or electronic systems. Therefore, a thorough understanding of the thermal expansion coefficients of materials is crucial for safe and efficient industrial and engineering applications.

2. Methods for measuring the coefficient of thermal expansion

Measuring the coefficient of thermal expansion is crucial for many industrial and scientific applications. It allows for the precise evaluation of how a material reacts to temperature changes, which is essential for sectors such as construction, aerospace, and electronics. Several laboratory methods have been developed to measure this coefficient with high accuracy. These techniques vary depending on the material's properties (solid, liquid, or gas) and the required precision for the analysis.

Dilatometry: the standard method for solids

Dilatometers are one of the most commonly used methods for measuring the thermal expansion of solids. A dilatometer is a high-precision instrument that measures the change in length of a solid sample in response to a change in temperature.

The dilatometry procedure generally follows these steps:

- Sample preparation : The sample is cut to a standard length and its surface is prepared to ensure good thermal transmission.

- Placement of the sample in the dilatometer : The sample is placed in a thermal chamber, often under an inert atmosphere (such as argon or nitrogen) to avoid chemical reactions.

- Temperature increase and control : The temperature is increased in a controlled manner. The dilatometer measures changes in length with high precision, generally on the order of a few micrometers.

- Calculation of the coefficient of thermal expansion : From the change in length ΔL and the temperature ΔT, the coefficient of linear expansion αL is calculated using the formula:

αL=ΔLL0ΔTαL=L0ΔTΔL

where L0L0 is the initial length of the sample.

Modern dilatometers use high-resolution sensors and highly accurate thermal control systems, enabling the measurement of coefficients of thermal expansion for a wide range of materials and temperatures, from -150°C to over 1000°C. This technique is particularly useful for metals, ceramics, and polymers, which are commonly used under extreme temperature conditions.

Thermomechanical analysis (TMA): precise measurement of thermal expansion

Thermomechanical analysis (TMA) is another thermal analysis method used to measure the coefficients of thermal expansion of solids, particularly when high accuracy is required. Like dilatometry, TMA measures the changes in length of a sample in response to a change in temperature, but it offers more diverse measurement modes for different materials.

The main measurement methods used in thermal expansion in thermal management include:

- Expansion method : A small weight is applied to the sample to measure linear expansion under the effect of temperature.

- Traction mode : The sample is subjected to a slight, traction force , which allows the expansion to be measured in a given direction.

- Volumetric mode : Particularly suitable for powders or granules, this mode allows measurement of volumetric variation under low applied pressure.

Thermal expansion thermograms (TATs) are often performed under an inert atmosphere to avoid undesirable reactions, and they allow for the creation of thermal expansion thermograms. These curves show the variation in sample length as a function of temperature, revealing additional thermal phenomena such as glass transition, phase change, or thermal degradation.

Measurement techniques for liquids: densimetry and pycnometry

The thermal expansion of liquids is measured mainly using densimeters and pycnometers, because the change in volume is greater in liquids than in solids.

- Densimetry : Vibrating tube densimeters, such as the DMA 5000M, measure the density of liquids with high accuracy and over a wide temperature range. By recording the density at different temperatures, the volumetric thermal expansion coefficient of the liquids can be calculated using the formula:

αV=1V0ΔVΔTαV=V01ΔTΔV

where V0V0 is the initial volume of the liquid.

- Pycnometry : This method is used to measure the density of liquids and, indirectly, their thermal expansion. It consists of measuring the volume of liquid contained in a calibrated container (the pycnometer) at different temperatures. By knowing the density of the liquid at different temperatures, it is possible to determine the coefficient of thermal expansion.

These techniques are particularly well-suited for liquids such as oils, solvents, and industrial fluids. Measuring the thermal expansion of liquids is essential for lubrication, cooling, and fluid transport applications in high-temperature environments.

X-ray diffraction for crystalline materials

For crystalline materials, such as ceramics or certain metals, X-ray diffraction is a commonly used method for determining coefficients of thermal expansion. It is particularly useful for anisotropic materials, whose thermal properties vary depending on the direction within the crystal structure.

This technique relies on measuring the crystal lattice parameters at different temperatures, which allows for the determination of the variation in length or volume as a function of temperature. The process generally follows these steps:

- Diffraction angle measurement : The diffraction angle changes depending on the temperature, revealing variations in the material's structure.

- Calculation of lattice parameters : From the diffraction angles, the interatomic distances in the crystal lattice are calculated. These distances vary with temperature, which allows the determination of thermal expansion.

- Calculation of the coefficient of expansion : The variation of the lattice parameters as a function of temperature allows the calculation of the linear coefficient of expansion for each crystallographic direction, particularly useful for anisotropic materials.

X-ray diffraction is a non-destructive, highly accurate method, essential for materials exhibiting anisotropy of thermal expansion. It is frequently used in research and development to design materials with controlled expansion, such as thermally stable composites.

Comparison of measurement methods: advantages and limitations

Each method for measuring the coefficient of thermal expansion has specific advantages and limitations, which vary depending on the material being studied and the desired experimental conditions.

| Method | Suitable materials | Precision | Temperature range | Benefits | Limitations |

|---|---|---|---|---|---|

| Dilatometry | Solids | High | -150°C to 1000°C | High precision, wide temperature range | Requires good thermal contact |

| TMA | Solids | Very high | -150°C to 1000°C | Multiple measurement modes, detailed thermograms | Expensive, sensitive to mechanical stress |

| Densimetry | Liquids | Average | 0°C to 100°C | Easy to use, quick measurement | Limited to liquids of stable density |

| Pycnometry | Liquids | Average | Room temperature | Simple, inexpensive | Indirect measure, limited to small volumes |

| X-ray diffraction | Crystals, anisotropic materials | Very high | Varies depending on the device | Highly accurate for anisotropic crystalline materials, non-destructive | High cost, specific equipment required |

Each method offers a level of accuracy and temperature range suited to specific applications.

3. Practical applications of thermal expansion and industrial challenges

Understanding and controlling the thermal expansion of materials is essential in many industrial sectors. The variation in material dimensions due to temperature can lead to significant technical and structural challenges. This section explores the main applications of thermal expansion, highlighting the sectors that must particularly consider this phenomenon to ensure the safety and effectiveness of their products.

Construction and civil engineering

In the construction industry, thermal expansion plays a crucial role in the stability and durability of infrastructure. Temperature variations lead to dimensional changes which, if not anticipated, can cause structural deformations and internal stresses.

- Expansion joints : Bridges, roads, and buildings must incorporate expansion joints, allowing materials to expand or contract without causing cracks or damage. These joints enable structures to withstand temperature fluctuations of several tens of degrees, thus preventing degradation due to thermal stress.

- Railway tracks : Rails expand and contract with temperature variations, which can lead to warping, especially in hot weather. Therefore, rails are installed with some clearance to prevent this type of problem. Specific materials, such as Invar steel (which has a very low coefficient of expansion), can also be used to mitigate these effects.

Aeronautical and space transport

In the aeronautics and space industries, materials undergo extreme temperature variations, whether during an aircraft's ascent to high altitude or a spacecraft's entry into the atmosphere. These thermal differences can affect the shape and strength of components, making the control of thermal expansion essential.

- Rockets and satellites : The structures of rockets and satellites are subjected to considerable temperature variations between the launch, orbital, and reentry phases. For example, the thermal coating on satellites must withstand the frigid temperatures of space as well as the intense heat of direct sunlight. Special materials, such as carbon-carbon composites, are used to withstand these extreme conditions while maintaining their dimensional stability.

- Low expansion materials : In aircraft, the phenomenon of thermal expansion is also taken into account in the design of the wings and the aircraft structure. The use of materials such as aluminum and titanium alloys, which offer a good compromise between lightness and thermal resistance, helps to guarantee the safety and performance of the aircraft.

Manufacturing and design of electronic products

In electronics, components are often exposed to temperature variations, whether during operation or due to environmental conditions. Thermal variations can cause cracks, deformations, or disconnections, especially at the microscopic level.

- Printed circuit boards (PCBs) : Printed circuit boards undergo significant temperature cycles, particularly during component soldering. Temperature variations can cause delamination or deformation that affects electrical conductivity. This is why materials such as glass fiber reinforced epoxy composites are often used due to their low coefficient of thermal expansion.

- Microprocessors and electronic chips : Microprocessors generate a significant amount of heat during operation. To prevent overheating and damage caused by thermal expansion, heat sinks and cooling systems are integrated. Furthermore, the materials used in chip manufacturing, such as silicon, are selected for their thermal stability properties.

Automotive industry

The automotive industry faces many challenges related to thermal expansion, as vehicles operate in varied environments and under high temperature stresses, particularly in engines and exhaust systems.

- Engines and exhaust systems : Engines generate significant heat, which causes the expansion of metal components. If this expansion is not controlled, it can lead to premature wear or cracking. Alloys with low thermal expansion, such as reinforced aluminum alloys or stainless steel, are often used for these applications.

- Automotive glazing : The glazing must withstand temperature variations between the inside and outside of the vehicle, particularly in summer and winter. Manufacturers use special glass, such as laminated glass, which resists thermal stress while ensuring good visibility.

Applications in composite materials and polymers

Composite materials and polymers play an important role in many sectors, including aerospace, automotive, and sports, thanks to their lightness and strength. However, their thermal expansion can be problematic, especially for multi-material composites.

- Multi-material composites : Composites are often made up of several types of materials with different coefficients of thermal expansion. For example, a composite made of carbon fibers and epoxy resin may exhibit uneven thermal expansion, leading to internal stresses. Studies on the coefficients of expansion of each component allow for the optimization of formulations and manufacturing processes to minimize these effects.

- Thermoplastic polymers : Polymers like polypropylene have high coefficients of thermal expansion. They are used in applications where a certain degree of flexibility is required. However, when exposed to extreme temperatures, they can deform. Stabilizing additives are often added to reduce their thermal expansion and improve their stability.

Issues related to thermal shocks and structural deformations

Thermal shock is a phenomenon where a rapid change in temperature causes internal stresses in a material. This can lead to fractures or structural deformations, particularly in brittle materials such as glass and ceramics.

- Glass and ceramics : Glass is particularly sensitive to thermal shock, which is why manufacturers often use borosilicate glass, known for its low thermal expansion, in applications requiring increased strength, such as laboratory containers or cooktops. Ceramics, on the other hand, are strengthened by heat treatments to improve their resistance to temperature variations.

- Industrial applications : In industries where components are subjected to rapid temperature changes, such as turbines or heating systems, materials must be able to withstand these variations without cracking. Engineers use materials with appropriate coefficients of thermal expansion and design them to distribute stresses evenly.

This third section illustrates the importance of considering thermal expansion in multiple sectors, where it impacts the safety, durability, and efficiency of structures and products. Materials and processes must be carefully selected and adapted to meet the specific requirements of each application.

Are you looking for an analysis?

4. Methods for measuring the coefficient of thermal expansion in the laboratory

Accurate measurement of the coefficient of thermal expansion is crucial for many industrial and scientific applications. Laboratories use various techniques to determine this parameter depending on the nature of the material, the temperature, and the specific requirements of the analysis. This section presents the most commonly used methods for measuring the coefficient of thermal expansion, along with their advantages and limitations.

Dilatometry: the reference technique

Dilatometry is one of the most frequently used methods for measuring the coefficient of thermal expansion, particularly for solids. The principle is based on measuring the dimensional changes of a sample subjected to a temperature variation.

- Principle : A sample is placed in a dilatometer, which measures its initial length. The temperature is then gradually increased or decreased, and the changes in length are recorded with high precision. The coefficient of linear thermal expansion (α) is then calculated as a function of the change in length, the initial temperature, and the final temperature.

- Advantages : Dilatometry allows for very precise measurement of length variations, even on small scales. It is suitable for various solid materials, from metals to ceramics and polymers.

- Limitations : This method is primarily suited to solids and is not appropriate for liquids or gases. Furthermore, it requires homogeneous and well-calibrated samples, which may limit its use for certain composites or anisotropic materials.

Thermomechanical analysis (TMA)

Thermomechanical analysis (TMA) is a thermal analysis method that measures the dimensional changes of a sample as a function of temperature. It is particularly used for polymer and composite materials, as well as ceramics.

- Principle : A sample is placed in a TMA device, where it is subjected to a slight load while being heated or cooled. The TMA measures changes in length with high precision while the temperature varies in a controlled manner.

- Measurement methods Several modes are possible in TMA:

- Expansion : The sample is supported by a fixed surface and a lightweight probe records the length variations.

- Traction : The sample is subjected to a constant tensile force, which allows its elongation to be measured.

- Compression : Used to measure the deformation properties of soft or compressible materials, this technique also allows tracking height variations.

- Advantages : The TMA is suitable for polymers and composite materials and allows for precise measurements over a wide temperature range.

- Limitations : It is less accurate than dilatometry for metals and ceramics, and samples must be of specific size and shape to be compatible with the device.

Measurement of thermal expansion of liquids: densimetry and pycnometry

Measuring the thermal expansion of liquids is more complex due to their fluid nature. Indirect techniques, such as densimetry and pycnometry, are often used to determine volume changes as a function of temperature.

- Densimetry : This method uses a vibrating tube densimeter to measure the density of a liquid at different temperatures. By measuring the density variations, it is possible to calculate the coefficient of volumetric thermal expansion.

- Pycnometry : A technique used to measure the density of liquids and certain solids, pycnometry can also be used to estimate thermal expansion. The volume changes of a liquid are determined by the density variation observed in a pycnometer at different temperatures.

- Advantages : These methods allow for the accurate measurement of the thermal expansion of liquids over a wide temperature range, and they are relatively simple to implement.

- Limitations : These techniques require specific equipment and careful sample preparation to avoid measurement errors related to volatility or impurities in liquids.

X-ray diffraction techniques for crystalline materials

X-ray diffraction (XRD) is a method used to analyze crystalline materials and measure their thermal expansion. By observing the changes in the crystalline structure as a function of temperature, it is possible to determine the coefficient of thermal expansion.

- Principle : Crystalline materials are exposed to X-rays, which produce a diffraction pattern. As the temperature increases, the interatomic distances widen, altering the diffraction pattern. By measuring these changes, the coefficient of thermal expansion can be calculated.

- Advantages : X-ray diffraction allows for very precise and detailed measurement, especially for anisotropic and multicrystalline materials, where expansion can vary according to directions.

- Limitations : This technique is expensive and requires specialized equipment. It is mainly reserved for research laboratories and is not suitable for amorphous materials or certain composites.

Simultaneous thermal analysis: TGA-DSC

Simultaneous thermal analysis, which combines thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), allows for the measurement of both mass variations and energy changes in a material as a function of temperature. Although this method does not directly measure thermal expansion, it provides essential complementary information about thermal transformations.

- Principle : When a sample is heated, TGA measures the mass loss or gain, while DSC records the heat fluxes. Mass changes can be related to decomposition, evaporation, or oxidation, and thermal transitions (melting, glass transition) are detected by DSC.

- Applications : This technique is useful for materials that undergo changes of state or chemical reactions at specific temperatures. It provides information on thermal transitions, essential for understanding the overall thermal behavior of a material.

- Limitations : TGA-DSC is not a direct method for measuring the coefficient of thermal expansion. However, it remains a complementary tool for analyzing heat-sensitive materials or those undergoing complex transformations.

Factors influencing the choice of measurement method

The choice of method for measuring the coefficient of thermal expansion depends on several factors related to the characteristics of the sample and the objectives of the analysis.

- Nature of the material : Solids, liquids, and crystalline materials require different methods. For example, dilatometry is preferred for metals, while densimetry is suitable for liquids.

- Analysis temperature : Some methods, such as TMA, are suitable for low temperatures, while X-ray diffraction is preferred for materials that need to be analyzed at very high temperatures.

- Anisotropy and isotropy : For anisotropic materials, it is crucial to use techniques that allow measurement of expansion variations in multiple directions, such as X-ray diffraction.

- Accuracy required : Accuracy depends on the application requirements. For example, dilatometry and X-ray diffraction offer high accuracy, while TMA is more general.

This fourth section highlights the various techniques used in laboratories to measure the coefficient of thermal expansion. Depending on the specific needs of industries, laboratories choose the most suitable method to provide accurate and reliable results, thus enabling them to anticipate and manage the effects of thermal expansion in critical applications.

5. Practical applications and challenges of thermal expansion in industry

Thermal expansion has significant implications in many industrial sectors, from materials engineering and construction to the aerospace and electronics industries. A precise understanding of the coefficient of thermal expansion is essential for avoiding structural problems, optimizing material performance, and designing durable and safe products. This final section explores the practical applications of thermal expansion in various industries, as well as the challenges associated with managing it.

Building and construction: managing dimensional variations

In the field of construction, thermal expansion is a phenomenon that must absolutely be taken into account to avoid structural damage, especially for large structures such as bridges, buildings and roads.

- Bridges and civil engineering structures : Bridges are subject to daily and seasonal temperature variations that affect their structure. To prevent internal stresses that could cause cracks or breaks, expansion joints are placed at regular intervals. These joints allow the structure to expand and contract without damaging the material.

- Roads and highways : Road surfaces are also susceptible to thermal expansion. Cracks can appear when materials expand or contract too rapidly. Engineers use specific asphalt mixes and expansion joints to limit damage and maintain road safety.

- Steel buildings and structures : Steel buildings also require thermal expansion devices to prevent excessive stress. Solutions such as expansion joints and floating fastening systems help minimize the risk of deformation.

Aerospace and automotive industries: materials adapted to extreme conditions

In the aerospace sector, materials undergo intense temperature variations, particularly during changes in altitude or re-entry into the Earth's atmosphere. The coefficients of thermal expansion of the materials used must be meticulously controlled to guarantee the stability of the structures.

- Low thermal expansion composite materials : Composite materials, such as aluminum-lithium alloys, are often preferred for their low coefficient of thermal expansion and their resistance to temperature variations. These materials allow for the design of more stable structures in the extreme conditions of space or high-altitude flight.

- Thermal panels : In spacecraft, thermal panels must maintain their shape despite very low temperatures in space and high temperatures during atmospheric reentry. Materials with low thermal expansion, such as invar alloys, are used to avoid mechanical stresses on the structure.

- Automotive industry : Thermal expansion is also taken into account in the design of engines and exhaust systems. These components, often in contact with high temperatures, are made of materials capable of withstanding thermal stresses without deforming.

Electronics and advanced technologies: miniaturization in the face of thermal constraints

In the field of electronics, thermal expansion represents a major challenge, especially with the miniaturization of components. The heat produced by electrical circuits causes expansion that can affect performance or damage devices.

- Microprocessors and integrated circuits : Electronic components heat up during operation. If the circuit material has a high coefficient of thermal expansion, this can cause microcracks and failures. Thermally stable materials, such as silicon and certain metal alloys, are often used to minimize the effects of expansion.

- Multi-material assemblies : Many electronic devices incorporate different materials, each with a specific coefficient of thermal expansion. Managing thermal stresses then becomes a challenge to prevent failures at solder joints and interfaces. Engineers must carefully select and assemble materials to ensure the durability of the components.

- Printed circuit boards (PCBs) : Printed circuit boards, often subjected to high temperatures, require materials with low thermal expansion to prevent warping. Special materials, such as Teflon and ceramics, are often used for high-performance applications.

Energy and resource management: the challenges of thermal expansion in power plants

Power plants, whether nuclear, solar or thermal, use materials subject to significant thermal variations, which implies rigorous management of thermal expansion.

- Nuclear power plants : Nuclear reactors operate at high temperatures and impose extreme thermal stresses on the materials of the pipes, vessels, and steam generators. The choice of materials, such as stainless steel alloys with a low coefficient of expansion, is essential to prevent leaks or cracks.

- Solar energy : Solar power plants concentrate heat onto receivers to produce electricity. The materials of the receivers and heat transfer tubes must be able to withstand significant temperature variations without deforming. Materials resistant to thermal expansion, such as borosilicate glass and certain metal alloys, are commonly used.

- Turbines and power generation equipment : Turbines in thermal and hydroelectric power plants are subject to temperature variations, particularly during start-up and shutdown phases. Thermal expansion is managed through the use of specific alloys and designs that allow for a certain level of flexibility.

Future challenges and innovations in thermal expansion management

The importance of thermal expansion is constantly growing with the evolution of technologies and the increasing performance requirements of materials. Research in this field focuses on the development of new materials and techniques to better control thermal effects.

- Materials with zero coefficient of thermal expansion : Composite materials developed to have a coefficient of thermal expansion of zero or close to zero are an active area of research. These materials, such as carbon fiber and ceramic composites, could eliminate stresses due to expansion in structures sensitive to temperature variations.

- Materials nanoengineering : Nanoengineering allows for the modification of the thermal properties of materials. For example, nanocomposites can be designed to have low thermal expansion, which is particularly useful for electronic components and miniaturized devices.

- Advanced Cooling Systems : In electronics and industrial systems, cooling systems are essential for controlling temperature and limiting the effects of thermal expansion. Technologies such as immersion cooling in thermally conductive liquids are increasingly being explored for demanding applications.

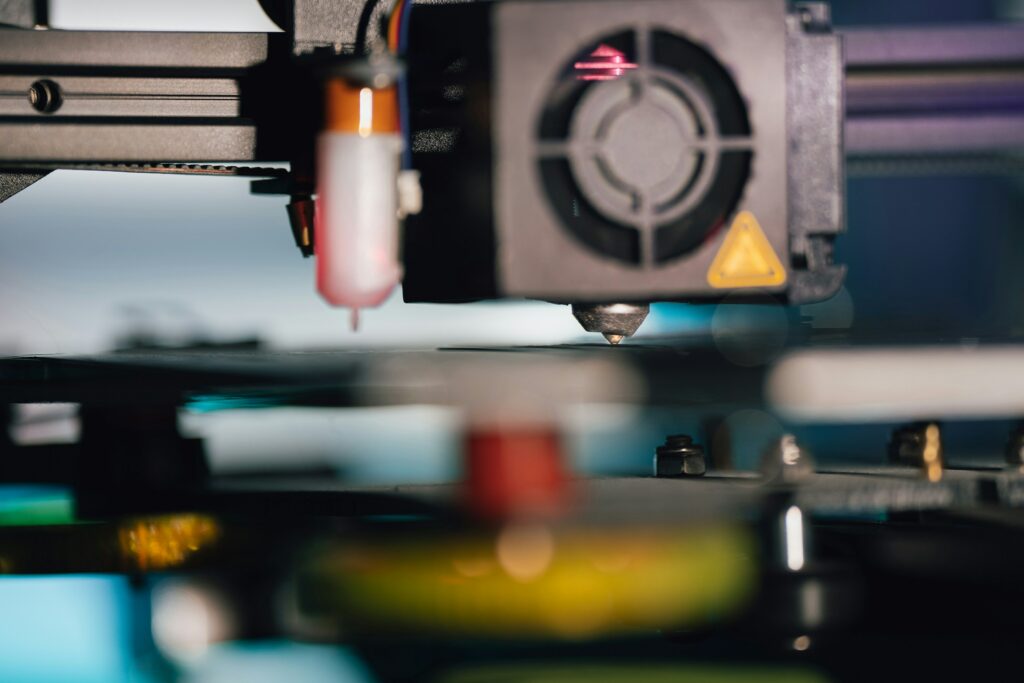

- 3D printing and custom design : Advances in 3D printing enable the manufacture of custom materials with thermal properties tailored to the specific needs of applications. This flexibility paves the way for more complex designs adapted to the thermal constraints of each environment.

This fifth section highlights the numerous applications of thermal expansion in modern industries and the challenges it presents. Mastering thermal expansion allows engineers to develop solutions tailored to the requirements of each sector, and ongoing research promises significant innovations to improve the performance and durability of materials.