UV-Visible spectroscopy is an essential analytical technique for the identification and quantification of numerous compounds in the laboratory. Used in diverse sectors such as food and beverage , pharmaceuticals, and environmental science, it allows for the analysis of substance concentration based on their ability to absorb light. This rapid and reliable method is widely used for quality control , contaminant detection, and the optimization of industrial formulations.

Whether you're a dietary supplement manufacturer , an environmental analysis , or a quality control manager, UV-Visible spectroscopy is an essential tool. Discover how YesWeLab can support you with its network of accredited partner laboratories, offering analytical solutions tailored to your needs.

1. Introduction to UV-Visible Spectroscopy

Definition and principle of UV-Visible spectroscopy

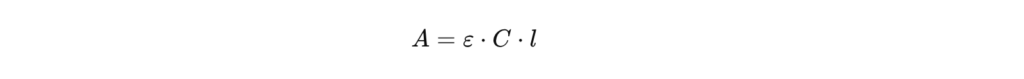

UV-Visible spectroscopy is ultraviolet (100-400 nm) and visible (400-750 nm) wavelength range . When radiation passes through a medium containing an absorbing substance, some of the light is absorbed while the rest is transmitted. The absorbance thus measured is directly related to the concentration of the compound of interest by Beer-Lambert's law :

Or :

- A is the absorbance,

- ε is the molar absorption coefficient (specific to each molecule),

- This is the concentration of the analyte.

- l is the length of the optical path through the sample.

This equation is the basis of spectrophotometric analyses in the laboratory and allows for the precise quantification of a substance from its absorption spectrum.

Importance of this technique in analytical chemistry and in the laboratory

Thanks to its simplicity and speed, UV-Visible spectroscopy has become a reference method in analytical chemistry . It provides crucial information on the optical properties of molecules , thus facilitating:

- The identification of chemical compounds by their unique absorption spectrum.

- The precise quantification of analytes in a sample.

- Real-time monitoring of chemical reactions

It is particularly appreciated in research and quality control laboratories because it allows non-destructive analyses , thus preserving the integrity of samples.

Application sectors and industries concerned

Food industry

- Analysis of polyphenols and antioxidants in beverages (wines, teas, fruit juices).

- Control of food colorings and verification of their regulatory concentration.

- Detection of contaminants and pesticide residues in food and drinking water.

Pharmaceuticals and biotechnology

- Dosage of active ingredients in drug formulations.

- Evaluation of the bioavailability of pharmaceutical molecules.

- Monitoring drug stability under different environmental conditions.

Cosmetics industry

- Quantification of UV filters in sunscreens.

- Analysis of pigments and preservatives in cosmetic formulations.

- Verification of product stability and monitoring of their aging.

Environment and regulatory analyses

- Detection of nitrates , phosphates and organic pollutants in drinking water and wastewater.

- Monitoring of polycyclic aromatic hydrocarbons (PAHs) in air and soil.

- Measurement of industrial contaminants released into the environment.

Materials and packaging

- Migration testing of chemical substances in food packaging (CE and FDA compliance).

- Analysis of polymers and paints to measure their UV resistance.

- Evaluation of the degradation of plastics and stabilizers.

Why is UV-Visible spectroscopy essential?

- Fast and reliable method : results obtained in seconds to minutes.

- Low cost of analysis : compared to other advanced analytical techniques (such as chromatography).

- High sensitivity : capable of detecting very low concentrations of absorbing compounds.

- Versatility : applicable to a wide range of industrial sectors.

Thanks to these numerous advantages, UV-Visible spectroscopy is an essential technique for analytical laboratories, guaranteeing precise and reproducible results , essential for industrial decision-making.

2. Principle, operation and instrumentation

Composition of a UV-Visible Spectrophotometer

A UV-Visible spectrophotometer is a laboratory instrument that measures the absorption of light by a sample at different wavelengths. It is composed of several essential elements.

light source

The spectrophotometer must emit a beam of light covering the UV (100-400 nm) and visible (400-750 nm) spectrum . The following are primarily used:

- Deuterium lamp : UV source, effective between 160 and 400 nm.

- Tungsten-halogen lamp : visible light source, effective between 320 and 1100 nm.

Monochromator and dispersion system

Before reaching the sample, the light is separated into different wavelengths using:

- Quartz prisms : used in some older instruments.

- Diffraction gratings : more common, as they offer better spectral resolution.

The role of the monochromator is to select a specific wavelength to perform the analysis.

Cuvettes and samples

The sample being analyzed is placed in a glass, plastic, or quartz dish

- Quartz cuvettes : used for UV measurements (transparency in UV).

- Plastic cuvettes : suitable for analyses in the visible range only.

The standard dimensions of the cuvettes are 1 cm optical path length , which corresponds to the parameter l in the Beer-Lambert equation.

Detectors and signal measurement

After passing through the sample, the residual light is captured by a detector , which converts the light intensity into an electrical signal.

- Photodiodes : used in conventional spectrophotometers, they measure light intensity at a given wavelength.

- Diode array detectors (DADs) : allow simultaneous recording of the entire UV-Visible spectrum, making analysis faster.

The signal is then processed by software which displays the absorption spectrum , allowing for a precise interpretation of the results.

Types of UV-Visible Spectrophotometers

There are different types of spectrophotometers adapted to the needs of laboratories.

1. Single-beam spectrophotometer

- The light passes first through a white (reference), then a second time through the sample.

- Simple to use, but requires repeated measurement for each sample.

2. Double-beam spectrophotometer

- Two beams are generated: one passes through the sample and the other through a reference blank simultaneously.

- Improved stability and reduced analytical errors.

3. Diode array spectrophotometer (DAD)

- Uses a detector array to simultaneously measure the entire UV-Visible spectrum.

- Speed of analysis and ability to study kinetic changes in real time .

These devices are used in many analytical laboratories , from quality control to environmental and pharmaceutical studies.

Why is instrumentation essential in UV-Visible spectroscopy?

The choice of spectrophotometer depends on several criteria:

- Range of wavelengths analyzed (UV, visible or both).

- Precision and sensitivity required depending on the application.

- Ability to analyze multiple samples simultaneously (e.g., multi-cuvette spectrophotometer).

- Ease of use and automation to optimize routine analyses.

By mastering these elements, laboratories can optimize the accuracy and reproducibility of measurements , guaranteeing reliable and usable analytical results within a strict regulatory framework.

Are you looking for an analysis?

3. Applications and analytical methods in the laboratory

Qualitative and quantitative analysis using UV-Visible spectroscopy

UV-Visible spectroscopy is widely used for the qualitative and quantitative analysis of many compounds. Its principle is based on measuring the absorption of light by a substance at a specific wavelength, which allows for the identification of an analyte and the evaluation of its concentration.

Qualitative analysis involves identifying a compound based on its absorption spectrum , which is unique to each substance. By comparing the spectrum of an unknown sample to a spectral database, it is possible to determine the presence of certain molecules.

Quantitative analysis , on the other hand, relies on Beer-Lambert's law to determine the concentration of an analyte in solution. This technique is widely used for:

- Determination of nitrates and phosphates in environmental analyses.

- Quantification of polyphenols in agri-food products.

- Determination of the concentration of active ingredients in pharmaceuticals and cosmetics.

Thanks to its precision and simplicity, UV-Visible spectrophotometry has become an indispensable tool in quality control and analytical research.

Techniques coupled with UV-Visible spectroscopy

UV-Visible spectroscopy can be coupled with other analytical techniques to improve the sensitivity and specificity of measurements.

1. HPLC-UV (High-Performance Liquid Chromatography with UV-Visible Detection)

- Widely used in pharmaceuticals and food processing for the analysis of complex mixtures.

- Allows separation of components prior to detection by UV-Visible.

- Typical application: dosage of flavonoids , antibiotics or vitamins.

2. UV-Vis coupling and fluorescence spectroscopy

- UV-Visible spectroscopy is often combined with fluorescence for better detection of molecules at low concentrations.

- Application in biochemistry and biotechnology : analysis of proteins, enzymes and nucleic acids.

3. Derivative spectroscopy and optimization of analytical signals

- It improves spectral resolution and eliminates optical interference .

- Useful for analyzing complex samples with multiple absorbing compounds.

- Applied in pharmaceuticals and formulation control .

These couplings make it possible to optimize analyses by increasing the accuracy and reliability of results , particularly in regulated sectors such as health, environment and agri-food.

4. Laboratory analyses using UV-Visible spectroscopy

UV-Visible Spectrophotometry Analysis Procedures

In the laboratory, UV-Visible spectroscopy is used to quantify compounds in solution by measuring their light absorption. This method relies on comparing the absorbance of a sample with a calibration curve obtained from standards of known concentration.

Analyte quantification by UV-Visible spectrophotometry

To measure the concentration of a compound, the procedure generally follows these steps:

- Sample preparation : dissolution in a UV-Visible compatible solvent (e.g. water, methanol, acetone).

- Selection of the optimal wavelength : identification of the λmax , i.e. the wavelength at which the compound absorbs most strongly.

- Calibration : creation of a calibration curve from solutions of known concentration.

- Absorbance measurement : passing the sample through the spectrophotometer and recording the spectrum.

- Concentration calculation : application of Beer-Lambert's law to determine the analyte content.

This technique is used for a wide variety of analyses, such as:

- Analysis of polyphenols and flavonoids in plant extracts and agri-food products.

- Quantification of nitrates and phosphates in environmental analyses.

- Determination of active ingredients in medicines and cosmetics.

Laboratory purity tests and quality control

Laboratories use UV-Visible spectroscopy to verify the purity of chemical substances and ensure their compliance with regulatory specifications.

- Pharmaceutical industry : validation of the concentration of active ingredients and control of excipients.

- Food industry : control of colorings and additives to avoid exceeding authorized thresholds.

- Environment : measurement of contaminants and pollutants in water and air.

One of the major advantages of this technique is that it allows for non-destructive analysis , which is essential for monitoring sensitive products.

Regulatory compliance testing (ISO 17025, COFRAC, international standards)

UV-Visible spectroscopy analyses must adhere to strict standards to ensure the reliability of the results.

- ISO 17025 standard : imposes requirements on the traceability and validation of analytical methods in the laboratory.

- COFRAC accreditation : in France, certified laboratories ensure the reliability and reproducibility of results .

- European and international regulations : in agri-food, pharmaceutical and environmental sectors, analyses must meet precise criteria defined by organizations such as the EFSA (European Food Safety Authority) or the FDA (Food and Drug Administration).

Tests carried out with certified equipment and validated methods ensure that the products comply with legal requirements and can be safely marketed.

Migration tests for materials in contact with food

In addition to food analyses, UV-Visible spectroscopy is used to assess the migration of substances from packaging into food.

- Compliance with EC Regulation No. 1935/2004 : guarantees that packaging materials do not release toxic substances into food.

- Release and extractables tests : analysis of solvents and plasticizers that can migrate from plastic packaging into food.

- FDA standards : For products intended for North American markets, strict criteria are established to limit the presence of contaminants in packaging materials.

These tests are essential to protect consumer health and ensure regulatory compliance of packaged products.

5. Advantages and limitations of UV-Visible spectroscopy

| Criteria | Benefits | Boundaries |

| Sensitivity | Detection of very low concentrations (μg/L to mg/L) | May be insufficient for some non-absorbing analytes |

| Speed | Results in seconds/minutes | Not suitable for complex analyses requiring separations |

| Cost | Low cost of instruments and consumables | Requires regular maintenance and calibration |

| Ease of use | Simple, automatable method, minimal sample preparation | Sensitive to optical and chemical interference |

| Sample type | Compatible with most liquid solutions | It does not allow for the direct analysis of solids or gases. |

| Interference | Good reproducibility with pure samples | Complex matrices can distort the results (coloration, turbidity) |

| Industrial applications | Wide range of applications (food processing, pharmaceuticals, environment) | May require coupling with other techniques for more complex analyses |

How can UV-Visible analyses be optimized despite these limitations?

To circumvent these constraints, laboratories use several strategies:

- Sample pretreatment : filtration, dilution or extraction to limit interferences.

- Use of coupled techniques : combination with chromatography (HPLC-UV) to separate compounds prior to analysis.

- Frequent calibration of instruments : regular verification with certified standards to ensure the accuracy of measurements.

Despite these limitations, UV-Visible spectroscopy remains a method of choice for many analytical applications, thanks to its excellent cost-effectiveness and ease of use in the laboratory.

6. Why choose YesWeLab for your UV-Visible spectroscopy analyses?

In a context where analytical precision and regulatory compliance are essential, working with a reliable laboratory is paramount. YesWeLab offers a complete solution for industrial companies wishing to perform UV-Visible spectroscopy analyses with reliable, compliant, and rapid results .

A network of accredited and expert laboratories

One of YesWeLab's main strengths is its large network of partner laboratories , selected for their expertise in spectroscopic analyses and their compliance with international standards.

- ISO 17025 and COFRAC accredited laboratories : guarantee validated methods and traceable results.

- Specialization by sector : YesWeLab works with expert laboratories in agri-food, pharmaceutical, cosmetic, environment and materials .

- Analyses adapted to current regulations : compliance with European (EC Regulation 1935/2004, EFSA) and American (FDA) standards.

Thanks to this approach, manufacturers can be assured that their UV-Visible analyses meet quality requirements and are recognized internationally.

A tailor-made service for manufacturers

Each industry sector has specific needs in terms of spectrophotometric analysis. YesWeLab offers personalized support to guarantee tailored solutions .

- Development and validation of analytical methods : implementation of customized protocols according to client requirements.

- Comparison and selection of the best techniques : choice of the optimal wavelength, analysis of potential interferences.

- Technical support and interpretation of results : expert guidance to understand and utilize analytical data.

Whether for regular quality control , regulatory compliance or R&D study , YesWeLab adapts to the specific requirements of each industrial company.

A digital platform to simplify analysis

YesWeLab offers a 100% digital service , allowing companies to manage their analyses efficiently and transparently .

- Centralization of analysis requests on a single interface.

- Real-time tracking of samples and rapid access to results.

- Secure archiving of analysis reports , facilitating traceability and quality audits.

This digital approach reduces delays and optimizes analytical costs , while ensuring better responsiveness for businesses.

Why choose YesWeLab for your UV-Visible analyses?

| Criteria | YesWeLab | Classical laboratory |

| Accreditation and compliance | Network of ISO 17025 and COFRAC certified laboratories | Depends on the laboratory's capabilities |

| Sector expertise | Laboratories specializing in specific fields (food processing, pharmaceuticals, cosmetics, etc.) | Generally non-specialized |

| Personalized support | Development of methods adapted to industrial needs | Standardized service |

| Digital platform | Management and monitoring of online analyses | Manual follow-up via email/phone |

| Time frame for obtaining results | Optimized through a network of partner laboratories | Variable depending on the laboratory's workload |

By choosing YesWeLab, manufacturers benefit from a fast, reliable service that complies with international standards , while also having access to an innovative digital interface to easily manage their analyses.

7. Perspectives and innovations in UV-Visible spectroscopy

UV-Visible spectroscopy, although established for decades as an essential technique in analytical chemistry, continues to evolve thanks to technological advances and the growing needs of industries . New approaches are emerging to improve the accuracy of analyses, accelerate processes, and expand areas of application.

Miniaturization and portable spectrophotometers

One of the major recent developments is the miniaturization of UV-Visible spectrophotometers . These increasingly compact and autonomous devices offer several advantages:

- On-site use : possibility of carrying out analyses directly in the field without going through a laboratory.

- Reduced analysis costs : less sample transport, faster results.

- Accessibility for SMEs and start-ups : reduced acquisition costs compared to conventional laboratory spectrophotometers.

The agri-food and environmental sectors particularly benefit from this advance, as it allows for on-site analysis of contaminants or active compounds , without waiting for the turnaround time of an external laboratory.

Automation and artificial intelligence in spectrum processing

The integration of artificial intelligence (AI) and machine learning into spectral data processing is a promising advancement. Thanks to these technologies, it becomes possible to:

- Automatically detect anomalies in a spectrum.

- Predicting the composition of a sample with greater accuracy, by reducing the influence of optical interference.

- Optimize analytical methods to obtain more reliable and reproducible results.

These innovations allow laboratories to optimize their workload and accelerate the interpretation of results , particularly in fields such as pharmaceuticals and biotechnology.

New materials to improve measurement accuracy

Researchers are also working on developing new optical materials to improve the sensitivity and robustness of spectrophotometric measurements. Among the innovations currently underway are:

- New semiconductor detectors enabling better spectral resolution.

- Cuvettes made of advanced materials (low dispersion glass, high-performance polymers) to limit optical losses and improve the reproducibility of analyses.

- High-performance LED light sources are gradually replacing tungsten and deuterium lamps, offering increased stability and reduced energy consumption .

These improvements will make the analyses even more reliable, accurate and accessible to a wide range of industrial applications.

Expanding industrial applications thanks to new technologies

The evolution of instruments and analytical techniques opens the way to new applications of UV-Visible spectroscopy.

- Biomarker detection in medicine : advanced spectrophotometers now make it possible to analyze certain biomarkers linked to neurodegenerative diseases or cancers.

- Analysis of microplastics in the environment : UV-Visible spectroscopy coupled with other spectroscopic techniques helps to identify the nature of microplastics present in water and soils.

- Real-time monitoring of industrial processes : with spectrophotometers integrated into production lines, it is possible to carry out continuous quality control to guarantee the conformity of manufactured products.

Conclusion

UV-Visible spectroscopy is becoming an essential analytical technique for many industrial and research sectors. Thanks to its simplicity, speed, and moderate cost, it allows for both the identification of compounds and the precise quantification of analytes in solution . Its use is particularly widespread in the food, pharmaceutical, cosmetic, environmental, and materials industries , where it plays a key role in quality control and regulatory compliance .

Why does UV-Visible spectroscopy remain essential?

- Versatility : it adapts to a wide range of analyses, from the dosage of active ingredients in pharmacy to the detection of pollutants in the environment.

- Reliability and accuracy : although it has some limitations, it offers reproducible results when properly calibrated.

- Accessibility : its implementation is simpler and less expensive than other analytical techniques, while remaining efficient.

- Technological innovations : automation, artificial intelligence and portable spectrophotometers are opening up new perspectives, making analyses even more efficient and accessible.

Whether for quality control, product validation or research and development needs , YesWeLab provides analytical solutions adapted to today's industrial challenges.

Need a reliable and fast UV-Visible analysis? Consult the YesWeLab catalogue and benefit from tailored support for your laboratory analyses.