ICP -MS ( Inductively Coupled Plasma Mass Spectrometry ) is a cutting-edge analytical technique for detecting and quantifying chemical elements at extremely low concentrations. Known for its high sensitivity and ability to analyze a broad spectrum of elements, it is widely used in diverse sectors such as food and beverage , healthcare, the environment , materials science, and nutraceuticals . This method allows for the precise identification of heavy metals, minerals, and other trace elements in various types of samples.

Thanks to its network of partner laboratories and its digital platform, YesWeLab facilitates access to ICP-MS analyses for manufacturers , guaranteeing a fast, accurate and compliant approach.

Table of Contents

Introduction

Trace element analysis has become a major issue in many industrial and scientific fields. Whether it's ensuring food safety , assessing the quality of cosmetic products , monitoring environmental contamination , or ensuring regulatory compliance of materials and packaging , the need for a precise and reliable analytical method is essential.

Among the various techniques available, inductively coupled plasma mass spectrometry (ICP-MS) stands out as an essential solution thanks to its ability to detect minute concentrations of chemical elements, even in trace amounts . Its versatility and sensitivity make it a benchmark tool for quality control laboratories, research institutes, and industrial companies.

In this article, we will:

- Define what ICP-MS is and how it works..

- Compare its performance with other analytical techniques.

- Explore its main industrial applications.

- Present the ICP-MS analysis solutions offered by YesWeLab and their advantages for businesses.

What is ICP-MS?

ICP -MS ( Inductively Coupled Plasma Mass Spectrometry ) is an advanced analytical technique for detecting and quantifying trace chemical elements . It is based on the combination of two fundamental principles:

- Ionization of elements by inductively coupled plasma (ICP) , which allows the transformation of atoms present in a sample into ions.

- The analysis of the generated ions using a mass spectrometer (MS) , which measures their mass/charge ratio to precisely identify and quantify each element.

History and evolution of ICP-MS

Inductively coupled plasma mass spectrometry was developed in the 1980s as a more efficient alternative to existing elemental analysis techniques, such as atomic absorption spectrometry (AAS) and plasma optical emission spectrometry (ICP-OES) .

Thanks to its enhanced sensitivity and speed , ICP-MS has rapidly become established in quality control laboratories, research institutions, and industries requiring detailed analysis of trace and ultratrace elements . Today, it has become an essential reference for the analysis of heavy metals, minerals, and other chemical contaminants in a variety of samples (water, food, cosmetics, biological matrices, polymers, etc.).

Comparison with other analytical techniques

ICP-MS is often compared to other methods of chemical element analysis, including:

| Technical | Sensitivity | Range of detectable elements | Benefits | Disadvantages |

|---|---|---|---|---|

| ICP-MS | Very high (ppt to ppb) | Wide range of items | Ultra-high trace detection, speed, precision | High cost, requires rigorous preparation |

| ICP-OES | Medium to high | Wide range of items | Less expensive than ICP-MS, suitable for medium concentrations | Less sensitive to marks and ultra-marks |

| AAS (Atomic Absorption) | Average | One element at a time | Proven and economical method | Long analysis time, less efficient for multi-element analyses |

ICP-MS is therefore distinguished by its ability to analyze several elements simultaneously with very high precision , making it an ideal solution for sectors requiring reliable and rapid results , such as agri-food, health, environment and nutraceuticals .

Are you looking for an analysis?

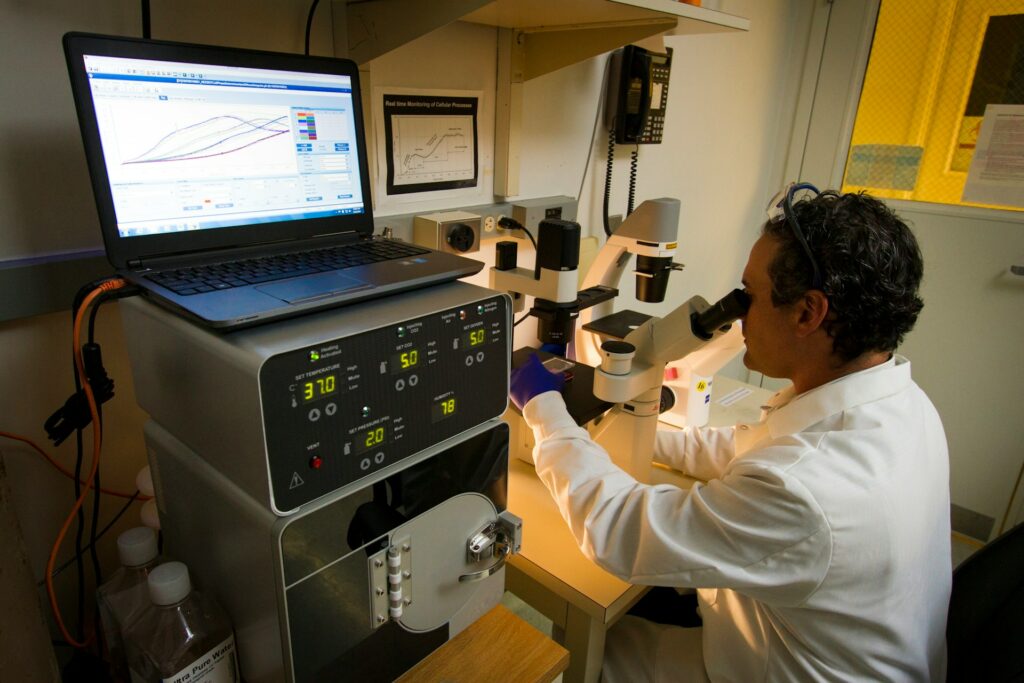

How does an ICP-MS work?

ICP -MS relies on a series of steps that transform a sample into ions, separate them according to their mass/charge ratio, and detect them with very high sensitivity . This process is divided into several key steps:

• Introduction and nebulization of the sample

The sample, usually in liquid form, is introduced into the system via a nebulizer , which transforms it into a fine aerosol . This phase is crucial, as it ensures homogeneous particles before they enter the plasma.

• Ionization in inductively coupled plasma (ICP)

Plasma, consisting of ionized argon at high temperature (approximately 6000 to 10,000 K) , plays an essential role in ICP-MS. It dissociates molecules and transforms atoms into positive ions .

The principle of inductive coupling relies on an electromagnetic field generated by a radio frequency coil . This field excites the electrons in the argon gas, forming an extremely hot plasma capable of ionizing the elements present in the sample.

• Extraction and focusing of ions

Once ionized, the ions are extracted from the plasma via a vacuum interface , which directs them to the mass spectrometer. This step removes excess gases and focuses only the ions of interest.

An electrostatic lens system then adjusts the ion flow , ensuring optimal transmission to the mass analyzer.

• Ion separation in the mass spectrometer (MS)

The ions then pass into a quadrupole or another type of mass analyzer. These devices act as selective filters , allowing the ions to be separated according to their mass/charge ratio (m/z) .

- The quadrupole is the most used: it applies an oscillating electromagnetic field, allowing only one type of ion to pass through at a time depending on its m/z.

- Other systems exist, such as TOF (Time of Flight) and magnetic sector analyzers , which allow even finer separations.

• Detection and quantification of elements

Once sorted, the ions are directed to a detector , which measures their intensity and converts these signals into elemental concentrations . Thanks to precise calibration curves, ICP-MS is able to provide quantitative results with extremely low detection limits (down to the ppt – parts per trillion scale).

• Interference correction

One of the major challenges of ICP-MS is managing spectral interference , which can distort the results. Various strategies are used to minimize these disturbances :

- Collision chamber or reaction cell : eliminates molecular interference by fragmenting unwanted ions.

- Internal calibration correction : improves accuracy by compensating for instrumental variations.

- Use of reactive gases (helium, hydrogen) to modify the trajectory of disruptive ions.

Why is ICP-MS so effective?

- Ultra-trace detection : allows quantification of elements in extremely low concentrations (ppt).

- Fast multi-element analysis : several elements can be detected simultaneously.

- Excellent accuracy and reproducibility : essential for industries subject to strict regulatory requirements.

Thanks to this performance, ICP-MS has become an essential tool for the food, pharmaceutical, cosmetic and environmental industries , enabling rigorous monitoring of contaminants and nutrients .

Advantages and limitations of ICP-MS

ICP -MS is a very powerful analytical technique, renowned for its extreme sensitivity and versatility . However, like any analytical method, it offers significant advantages , but also certain limitations that are essential to understand.

Advantages of ICP-MS

1. Exceptional sensitivity and precision

ICP-MS is capable of detecting extremely low concentrations of chemical elements, down to the ppt (parts per trillion) level. This sensitivity makes it the reference technique for the analysis of heavy metals and trace elements in various samples (water, food, cosmetics, biological matrices, etc.).

2. Rapid Multi-Element Analysis

Unlike atomic absorption spectroscopy (AAS), which only allows the analysis of one element at a time, ICP-MS offers the possibility of quantifying several elements simultaneously, thus considerably reducing analysis time.

3. Extended detection range

ICP-MS can analyze virtually all elements of the periodic table, including those present in very low concentrations. This versatility is essential in fields such as the environment, health, and agri-food, where rigorous monitoring of contaminants is necessary.

4. Fast analysis and high sample throughput

Thanks to an average analysis time of less than 1 minute per sample, ICP-MS is particularly suited to quality control laboratories, requiring high analytical throughput while guaranteeing accurate and reproducible results.

5. Excellent reproducibility and reliability of results

The measurements obtained by ICP-MS are highly reproducible, which is essential to ensure regulatory compliance and rigorous monitoring of agri-food, nutraceutical and cosmetic products.

6. Application to a wide variety of matrices

ICP-MS is compatible with different types of matrices, ranging from liquid samples (water, drinks, serums) to solids (soils, materials, food, polymers), after appropriate preparation.

Limitations of ICP-MS

1. High cost of instrumentation

ICP-MS is an advanced technology that requires a significant initial investment, with a purchase cost that can reach several hundred thousand euros, not including maintenance and consumable costs (argon gas, calibration solutions, etc.).

2. Need for technical expertise

Interpreting the results requires advanced expertise, particularly for correcting spectral interferences and optimizing analysis conditions. Without a qualified operator, analytical errors can occur.

3. Sensitivity to interference

Certain spectral and non-spectral interferences can affect the accuracy of the results. Although solutions such as collision cells and reactive gases exist to mitigate these effects, they add further complexity to the analysis.

4. Need for rigorous sample preparation

Because ICP-MS is extremely sensitive, the presence of impurities or particles in the samples can distort the results. Careful preparation, such as mineralization of solids or dilution of solutions, is often necessary.

5. High argon consumption

Inductively coupled plasma uses a large quantity of argon gas, a relatively expensive element. This significant consumption represents an economic factor to consider for laboratories performing a large number of analyses.

Applications of ICP-MS in industry

ICP-MS is widely used in many industrial sectors due to its sensitivity, accuracy, and ability to detect trace elements in a variety of samples. This technique plays a key role in quality control, regulatory compliance, and contaminant detection .

Agri-food: contaminant detection and mineral analysis

In the food , ICP-MS is used for:

- Detecting heavy metals (lead, cadmium, mercury, arsenic) in food products.

- Analyze the mineral composition of foods and drinks (calcium, iron, zinc, magnesium).

- Control the contamination of food packaging , including the migration of toxic substances from packaging materials into food.

- Verify compliance with European and international regulations (INCO regulation, Codex Alimentarius).

ICP-MS is particularly useful for the analysis of products from organic farming , where contaminant levels must be strictly controlled.

Health and cosmetics: control of toxic substances

ICP-MS is used to ensure the safety of health and cosmetic products by identifying the possible presence of contaminants:

- In medicines and pharmaceutical raw materials , to detect metallic impurities that may affect the effectiveness of the product or cause adverse effects.

- In cosmetics and personal care products , to check for the presence of heavy metals and other regulated contaminants (nickel, lead, arsenic, cadmium).

- In medical devices , to ensure that no undesirable elements migrate into the body during their use.

ICP-MS analyses are essential to comply with European Pharmacopoeia REACH regulations FDA requirements .

Environment: pollution monitoring

ICP-MS is a preferred tool for environmental monitoring and pollutant detection in natural environments . It is commonly used for:

- Analysis of drinking water and wastewater to detect toxic elements (lead, arsenic, chromium, copper).

- Soil and sediment control , particularly in the context of environmental impact studies and the remediation of industrial sites.

- Monitoring industrial emissions , to measure concentrations of metals in ambient air and limit human exposure to air pollutants.

Environmental laboratories rely on ICP-MS to ensure compliance with WHO standards, the European Water Framework Directive and ICPE regulations .

Materials and polymers: migration control and material purity

ICP-MS is essential for quality control of materials and polymers, particularly in:

- Analysis of metals in plastics and composite materials , to ensure that no toxic contaminants are present.

- Migration tests of food and pharmaceutical packaging , to verify that chemical substances do not transfer to the products they contain.

- Controlling the purity of metals and alloys used in aeronautics, automotive and other high-tech industries.

In this area, ICP-MS helps to meet the requirements of ISO standards and European and American regulations .

Nutraceuticals: Analysis of dietary supplements

With the dietary supplement market booming, ICP-MS has become a key tool for:

- Analyze the content of essential minerals (iron, calcium, magnesium, zinc) and ensure compliance with the declared doses.

- Detect heavy metals and undesirable contaminants in natural ingredients (algae, plant extracts, protein powders).

- Verify product compliance with European (EFSA) and American (FDA) regulations.

Dietary supplement manufacturers use ICP-MS to ensure the safety and quality of their products before they are placed on the market.

Nuclear industry and metallurgy: control of radioactive elements and strategic metals

In the nuclear and metallurgical , ICP-MS is used for:

- Analyze radioactive isotopes in nuclear materials and waste.

- Controlling the purity of precious and strategic metals (gold, platinum, rare earths).

- Detecting the presence of metallic contaminants in industrial manufacturing processes.

ICP-MS enables high-precision isotopic analyses , essential for applications requiring strict traceability of chemical elements.

ICP-MS analyses offered by YesWeLab

Since ICP-MS is an essential analytical technique for many industrial sectors, YesWeLab offers simplified access to this method through its network of partner laboratories and its digital platform . This allows manufacturers to obtain reliable, rapid analyses that comply with regulatory standards , without having to invest in expensive equipment or mobilize specialized internal resources.

Why go through YesWeLab for an ICP-MS analysis?

YesWeLab offers a turnkey solution for ICP-MS analyses, with several advantages:

- Direct access to over 200 specialist laboratories , equipped with the latest ICP-MS technologies.

- Optimized analysis times , thanks to a selection of high-performing and responsive laboratories.

- Complete traceability of samples , via a digital platform allowing real-time monitoring.

- Compliance with applicable standards (ISO 17025, COFRAC, REACH, European Pharmacopoeia, etc.).

- Personalized support , with experts available to interpret the results and advise on applicable regulations.

Collaboration process with YesWeLab

Using the YesWeLab platform simplifies access to ICP-MS analyses in just a few steps :

- Find your ICP-MS analysis among more than 10,000 references available on the platform.

- Ship your samples through a simplified process with detailed instructions.

- Receive your results online , with expert interpretation to guide you in their use.

Thanks to this digital approach, manufacturers benefit from a smooth and efficient service, allowing them to optimize their quality control without administrative complexity .

YesWeLab's competitive advantages

- Flexibility and accessibility : possibility to order one-off or recurring ICP-MS analyses, adapted to the specific needs of each company.

- Intuitive digital platform : centralization of analytical requests, results and sample tracking.

- Compliance with regulatory requirements ISO 17025 , COFRAC standards , and other regulations specific to each sector.

- Responsive and expert customer service : dedicated support to answer technical and regulatory questions.

ICP -MS is now one of the most advanced techniques for the analysis of trace elements. Thanks to its exceptional sensitivity , speed of execution and versatility , it has become an indispensable tool in many industrial sectors, including agri-food, health, environment, cosmetics and nutraceuticals .

However, this method requires expensive equipment and specialized expertise to ensure accurate analyses that comply with regulatory requirements . This is where YesWeLab comes in, offering a turnkey solution that allows manufacturers to access ICP-MS analyses without constraints.

Whether you are a food manufacturer, a quality manager in the cosmetics industry, or an environmental sector player , YesWeLab allows you to obtain reliable, fast and tailored analyses .