Mineral oil hydrocarbons, known by the acronyms MOSH and MOAH ( mineral oil saturated hydrocarbons and mineral oil aromatic hydrocarbons ), are petroleum-derived compounds that are causing increasing concern in the food industry. These substances can contaminate food through various means, including packaging , industrial lubricants, and processing additives. Due to their proven presence in numerous food products and the potential health risks they pose, stricter regulations are being implemented to limit their concentration.

This article explores in detail what MOSH and MOAH are, their sources of contamination, their health effects, and the analytical methods used to detect them. We will also examine solutions for minimizing their presence in consumer products and how manufacturers can comply with current standards.

YesWeLab offers a wide range of analyses dedicated to the detection of hydrocarbons in mineral oils, enabling manufacturers to secure their products and meet regulatory requirements.

Introduction to MOSH and MOAH

Mineral oil hydrocarbons are present in the environment and are frequently found in food. They originate primarily from manufacturing processes and materials used in the food industry. Contamination can occur at various stages, from raw material processing to final packaging.

Definition of mineral oil hydrocarbons

Mineral oil hydrocarbons (MOHs) are complex mixtures of chemical compounds derived from crude oil refining. They are divided into two main categories:

- MOSH (mineral oil saturated hydrocarbons) : these include saturated hydrocarbons, comprising linear and branched alkanes as well as cycloalkanes. These substances can accumulate in the human body, particularly in the liver and spleen.

- Mineral oil aromatic hydrocarbons (MOAHs) encompass alkylated and non-alkylated aromatic hydrocarbons, characterized by the presence of benzene rings. MOAHs with three or more aromatic rings are of particular concern due to their carcinogenic and genotoxic potential.

MOSH and MOAH are often detected together in laboratory analyses because they coexist in petroleum products. Their identification and quantification are essential for assessing health risks and ensuring food safety.

History of the discovery of mosh and moah in food

Mineral oil hydrocarbons have been studied for several decades, but their presence in food was highlighted on a large scale from the 2000s onwards. In 2010, a study carried out by the European Food Safety Authority (EFSA) revealed that food contamination by MOSH and MOAH was more widespread than expected.

In 2015, the DGCCRF (Directorate General for Competition Policy, Consumer Affairs and Fraud Control) published the results of an investigation into food packaging. This study revealed a significant migration of mineral hydrocarbons from recycled cardboard into food products. Following these findings, several European countries strengthened their regulations and implemented maximum limits to restrict contamination.

In 2023, the EFSA reassessed the hazards of MOHs and confirmed that MOAHs represent a major health risk , particularly due to their potential carcinogenicity. A proposed European regulation now aims to set strict maximum limits for these substances.

Why are mosh and moah a food security issue?

The presence of mineral oil hydrocarbons in food poses several problems:

- Risk to human health : MOSH tend to accumulate in adipose tissue and the liver, while MOAH are suspected of being carcinogenic and endocrine disruptors.

- Widespread contamination : MOSH and MOAH can be found in a wide range of food products, including vegetable oils, cereals, chocolate and infant foods.

- Difficulty in control : contamination can occur at several levels of the production chain, making it complex for manufacturers to control.

- Evolving standards : regulations are becoming increasingly strict, forcing companies to adapt their manufacturing processes and packaging.

Faced with these challenges, laboratory analysis is essential to detect the presence of MOSH and MOAH and ensure product compliance with regulatory requirements. Modern analytical techniques now allow for the identification of these hydrocarbons with high precision and the assessment of the potential risks associated with their ingestion.

Definition and classification of MOSH and MOAH

Mineral oil hydrocarbons (MOHs) are a group of chemical compounds derived from crude oil. They are ubiquitous in the environment and can contaminate food through various means, including packaging and industrial processes. They are primarily divided into two categories: MOSHs (mineral oil saturated hydrocarbons) and MOAHs (mineral oil aromatic hydrocarbons). Distinguishing between them is crucial because their toxicity and health impacts differ significantly.

What is a saturated mineral oil hydrocarbon?

MOSH (mineral oil saturated hydrocarbons) are saturated hydrocarbons composed of linear and branched alkanes as well as alkylated cycloalkanes . Their chemical structure gives them particular stability, which explains their persistent presence in biological tissues.

MOSH characteristics:

- Chemical structure : molecules made up exclusively of carbon and hydrogen, without aromatic rings.

- Main source : oil refining, certain food additives, lubricants, release agents.

- Health risk : tendency to accumulate in the liver and lymph nodes. Animal studies have shown a correlation between chronic ingestion and adverse effects on lipid metabolism.

MOSH can be found in food in the form of paraffins , often used as release agents in the food industry. They can also migrate from food packaging, especially packaging made with recycled paper.

What is an aromatic hydrocarbon of mineral oil?

MOAHs ) comprise a family of molecules containing one or more aromatic rings , often derived from crude oil refining. These hydrocarbons are of particular concern due to their carcinogenic and mutagenic potential .

MOAH characteristics:

- Chemical structure : hydrocarbons composed of one or more benzene rings, often substituted by alkyl groups.

- Main source : crude oil, printing inks, lubricants, industrial oils.

- Health risk : MOAHs with more than three aromatic rings are suspected of being genotoxic and carcinogenic .

ANSES (2017) and EFSA (2023) have classified MOAH among the most concerning contaminants in human food. Their detection and quantification in food products are now priorities for analytical laboratories.

What is the difference between MOSH and MOAH?

Although MOSH and MOAH have the same petrochemical origin, they differ fundamentally in their chemical structure and their effects on health:

| Characteristic | MOSH (saturated hydrocarbons) | MOAH (aromatic hydrocarbons) |

|---|---|---|

| Chemical structure | Alkanes and cycloalkanes | Aromatic hydrocarbons |

| Potential toxicity | Accumulation in tissues | Suspected carcinogens |

| Presence in food | Paraffins, waxes, lubricants | Inks, industrial oils |

| Regulatory impact | Increased surveillance | Strict limits recommended by EFSA |

The differences between these two classes of hydrocarbons explain why MOAH are more strictly regulated than MOSH. However, the presence of both types in consumer products remains a major issue.

Other hydrocarbons of concern: POSH and PAO

Besides MOSH and MOAH, other hydrocarbons present in food are attracting the attention of researchers and health authorities.

- POSH (polyolefin oligomeric saturated hydrocarbons) : saturated hydrocarbons derived from polyolefin plastics (PE and PP). These compounds can migrate into food via plastic packaging and present a risk that is still poorly understood.

- PAO (poly alpha olefins) : synthetic isoparaffins used in lubricants and some adhesives. Their presence in the food environment could pose an additional contamination problem.

POSH and PAO are not yet subject to regulations as strict as MOSH and MOAH, but their monitoring is increasing.

The distinction between MOSH, MOAH, POSH and PAO is essential to understanding the extent of hydrocarbon contamination of mineral oils and to guiding risk reduction efforts in the food industry.

Sources of food contamination

Mineral oil hydrocarbons (MOSH and MOAH) contaminate food at various stages of production, processing, and packaging. This contamination can be direct , when food comes into contact with a source containing MOH, or indirect , when the hydrocarbons migrate gradually from surrounding materials.

Origins and modes of contamination

Contamination by MOSH and MOAH can originate from several industrial and environmental sources. Three main sources :

- Migration from food packaging : the main source of food contamination, particularly via recycled inks, adhesives and cardboard.

- Contamination during manufacturing processes : presence of MOH in machine lubricants, release agents or technological auxiliaries.

- Environmental exposure : deposition of mineral oil residues from exhaust gases, industrial pollution or pesticides.

These hydrocarbons can also accumulate in raw materials used for food production, thus amplifying the risk of contamination.

Which foods are most affected?

products most affected by MOSH and MOAH contamination are those with a high fat content , because mineral oil hydrocarbons are lipophilic and dissolve easily in fats.

Main categories of contaminated food:

- Vegetable oils : the main vector of contamination, as they easily absorb mineral hydrocarbons present in the environment or packaging.

- Dairy products : butter, cream, cheeses and yogurts may contain traces of MOSH and MOAH due to the lubricating agents used in the dairy industry.

- Cereals and cereal products : biscuits, breads and pasta are often exposed to MOSH/MOAH via recycled cardboard packaging and dust suppressants used in grain processing.

- Chocolate and cocoa products : packaging and certain industrial processes promote the migration of hydrocarbons into these fat-rich products.

- Canned fish : the oils used to preserve canned fish are frequent vectors of contamination.

- Infant foods : special attention is paid to this category, as babies are more vulnerable to chemical contaminants. Since 2019, EFSA has recommended a maximum threshold of 1 mg/kg for MOAH in these products .

- Spices and oilseeds : contaminants can accumulate during storage or transport, particularly due to packaging and surface treatment agents.

These foods require rigorous analytical control , particularly for exports to countries applying strict thresholds on mineral oil hydrocarbons.

What are the edible mineral oils?

Some mineral oils are intentionally used in the food industry for technological reasons. They are distinguished from undesirable MOSH and MOAH oils by their purity and compliance with health regulations.

Examples of permitted edible mineral oils:

- E905 (food grade paraffin oil) : used as a glazing agent for fruit or confectionery.

- Mineral oils for the treatment of wine and fruit juice : used to remove impurities and stabilize certain beverages.

- Food-grade lubricants (NSF-H1) : Special oils used in food processing equipment, designed to limit the risk of contamination.

These oils are strictly controlled and must meet purity standards defined by European and international regulations. However, non-food-grade mineral oils contained in MOSH and MOAH do not meet these criteria and must be removed from consumer products.

Is it safe to put mineral oil in food?

The use of mineral oils in food is strictly regulated and depends on the type of oil used.

Cases where the use of mineral oil is permitted:

- Release agent to prevent food from sticking to industrial molds.

- Surface treatment agent to improve the visual appearance of fruits and vegetables.

- Food-grade lubricants in processing machinery.

Cases where mineral oil is prohibited or problematic:

- Unintentional migration from recycled cardboard packaging.

- Cross-contamination during the transport or storage of raw materials.

- Presence of carcinogenic MOAH in unrefined oils.

Manufacturers must ensure that the mineral oils they use comply with legal limits and pose no health risks to consumers. To this end, laboratory analyses are essential to detect the presence of MOSH and MOAH in food products.

Regulations concerning mineral oil hydrocarbons are constantly evolving. Contamination thresholds are set by health authorities, requiring manufacturers to adapt their processes to guarantee consumer safety.

Health risks associated with MOSH and MOAH

The presence of MOSH and MOAH in food is a major concern due to their potential effects on human health . Saturated hydrocarbons (MOSH) are likely to accumulate in the body , while aromatic hydrocarbons (MOAH) are suspected of having carcinogenic and endocrine-disrupting effects . Several scientific studies and regulatory assessments have highlighted these risks, prompting health authorities to strengthen monitoring and regulation.

Health effects of MOSH

MOSH (mineral oil saturated hydrocarbons) are saturated hydrocarbons composed of linear and branched alkanes. They are of primary concern due to their capacity for bioaccumulation in organs.

Bioaccumulation mechanisms and affected organs

- Liver : studies on animal models have shown that MOSH accumulate in the liver, potentially causing hepatic hypertrophy and disturbances in lipid metabolism.

- Spleen and lymph nodes : MOSH deposits have been observed in the lymphatic system , leading to cellular changes that may alter the immune response.

- Adipose tissue : their lipophilic nature promotes their storage in body fat.

Observed toxic effects

- Animal studies have revealed that chronic exposure to MOSH can lead to liver inflammation , fibrosis , and metabolic abnormalities.

- In humans, although the long-term effects are still being evaluated, the bioaccumulation of MOSH is considered a concern by EFSA and ANSES .

Current research focuses on the relationship between MOSH exposure and metabolic diseases , including liver dysfunction and lipid storage disorders.

Effects of MOAH on health

MOAHs ) toxicologically concerning mineral oil hydrocarbons . They contain aromatic rings , some of which are classified as carcinogenic and genotoxic .

Carcinogenic risk of MOAH

- MOAHs with more than three aromatic rings are particularly dangerous because they can intercalate into DNA and cause genetic mutations.

- The European Chemicals Agency (ECHA) classifies certain polycyclic aromatic hydrocarbons (PAHs) present in MOAH as known carcinogens .

- EFSA (2023) recommends the total elimination of MOAH in food due to their danger.

Endocrine-disrupting effect of MOAH

- Studies suggest that MOAHs could interfere with hormones by altering the expression of certain cellular receptors.

- ANSES (2017) highlighted a potential for endocrine disruption , particularly with regard to sex and thyroid hormones .

These observations have led several health authorities to demand strict monitoring of MOAH , with maximum contamination limits to ensure consumer safety.

Chronic exposure to MOSH and MOAH: what are the long-term risks?

Exposure to hydrocarbons from mineral oils is concerning because it is cumulative . Regular ingestion, even in small doses, could have long-term health consequences .

Main long-term risks

- Alteration of lipid metabolism : accumulation of MOSH in the liver and adipose tissues.

- Increased risk of cancer : particularly for MOAHs containing multiple aromatic rings.

- Immune disorders : changes observed in the lymph nodes and spleen.

- Hormonal interference : disruption of endocrine functions.

Long-term cohort studies are currently underway to more precisely assess the impact of MOSH and MOAH on human health.

Recommendations from health agencies

Faced with the potential risks of MOSH and MOAH, several organizations have published official recommendations aimed at limiting the population's exposure.

Recommendations from EFSA (European Food Safety Authority)

- Avoid any presence of MOAH in food due to its potential carcinogenic risk .

- Limit exposure to MOSH , especially in products with high fat content.

- Setting contamination thresholds for foodstuffs (draft regulation underway since 2023).

Recommendations from ANSES (French Agency for Food, Environmental and Occupational Health & Safety)

- Reducing exposure to mineral oil hydrocarbons through the removal of MOAHs in food packaging.

- Implementation of enhanced controls to identify sources of industrial contamination.

- Strengthening analytical testing to ensure the absence of MOAH in infant foods and vegetable oils.

European regulations in progress

- In 2022, SCOPAFF (Standing Committee on Plants, Animals, Food and Feed) recommended the withdrawal of food products containing more than 0.5 mg/kg of MOAH .

- Draft Regulation (EU) 2023/915 aims to impose maximum limits for aromatic hydrocarbons in all food categories.

Monitoring of these substances is set to increase in the coming years , requiring manufacturers to comply strictly to guarantee food safety.

Impact on the agri-food industry and precautionary measures

Regulations and health concerns surrounding MOSH and MOAH have a direct impact on the food industry . Manufacturers must adapt their practices to minimize contamination and meet the requirements of consumers and regulatory authorities .

Measures implemented by manufacturers

- Rigorous selection of raw materials to avoid upstream contamination.

- Replacing recycled paper packaging with mineral oil-free alternatives.

- Use of food-grade lubricants that comply with NSF-H1 standards.

- Strengthening laboratory analyses to control MOSH and MOAH levels in finished products.

Why are laboratory analyses essential?

- They allow for the rapid identification of sources of contamination and ensure regulatory compliance .

- They help ensure product quality and protect the reputation of food brands.

- They play a key role in anticipating new standards to avoid costly product recalls.

The management of mineral oil hydrocarbons has become a strategic issue for the agri-food industry. The implementation of rigorous analytical protocols is now essential to ensure compliance and protect consumer health.

Regulations and threshold limits for mosh and moah

Faced with the potential health risks associated with mineral oil hydrocarbons, European and international health authorities have established contamination thresholds and strict regulations . The aim is to control their presence in food products and to impose rigorous control procedures .

Developments in European standards

Regulations concerning MOSH and MOAH have evolved gradually, as scientific studies have confirmed their harmfulness.

Key stages of regulation in Europe

- 2012 : The EFSA (European Food Safety Authority) publishes an initial opinion highlighting the frequent contamination of food by MOSH and MOAH.

- 2015 : The DGCCRF (France) identifies a high migration of mineral hydrocarbons from recycled cardboard packaging.

- 2017 : ANSES recommends a reduction in exposure to MOSH and MOAH , particularly in products intended for infants .

- 2022 : The SCOPAFF (Standing Committee on Plants, Animals, Food and Feed) proposes the immediate withdrawal of products containing more than 0.5 mg/kg of MOAH .

- 2023 : The European Commission is working on strict regulations incorporating maximum limits for mineral oil hydrocarbons in food.

The evolution of these standards shows a growing awareness and a desire to limit as much as possible the presence of MOSH and MOAH in everyday consumer products.

Acceptable contamination thresholds

EFSA and the European Commission have established maximum contamination levels for MOAH in different food categories.

| Food type | Maximum MOAH threshold (mg/kg) |

|---|---|

| Low-fat dry foods (≤ 4%) | 0.5 mg/kg |

| Foods high in fat (> 4% fat) | 1 mg/kg |

| Oils and fats (> 50% fat) | 2 mg/kg |

These limits apply only to MOAH , considered the most toxic. For MOSH , EFSA recommends limiting their presence as much as possible , although no official threshold has yet been set.

Food packaging regulations

Food packaging, especially that made from recycled paper and cardboard , is a major source of contamination by mineral oil hydrocarbons.

Current regulations regarding packaging:

- Regulation (EU) No 1935/2004 : requires that materials in contact with food must not transfer harmful substances to food.

- French decree of April 13, 2022 : prohibits the use of certain mineral oils in printing inks and food packaging.

- EFSA recommendations : encourage the use of functional barriers to prevent the migration of MOSH and MOAH into food.

Manufacturers must ensure that their packaging meets these safety requirements , or face product recalls or regulatory penalties .

Impact of regulations on manufacturers

The implementation of strict regulations requires manufacturers, distributors and suppliers to adapt quickly to avoid contamination of food products.

Consequences for agri-food companies:

- Packaging adaptation : manufacturers must replace non-compliant recycled cardboard with barrier materials that limit the migration of mineral hydrocarbons.

- Strengthening quality controls : implementation of regular analyses of raw materials, packaging and finished products.

- Compliance with new standards : anticipating regulatory changes to avoid costly product recalls and preserve brand image.

- Seeking alternatives to industrial lubricants : adoption of NSF-H1 food-grade lubricants to limit the presence of MOSH in production machines.

These regulatory constraints have a direct economic impact on businesses, but they are essential to guarantee food safety and reassure consumers .

Controls and penalties in case of non-compliance

Health authorities carry out regular checks to ensure that products placed on the market comply with regulatory thresholds for MOSH and MOAH.

Main control measures:

- Official analyses by the DGCCRF and the EFSA to verify the conformity of food and packaging.

- Withdrawal of non-compliant products : in 2022, several products were withdrawn from the market after exceeding the authorized thresholds.

- Financial penalties and massive reminders for companies not complying with regulations.

Recent examples of recalls related to mineral oil hydrocarbons

- 2019 : Infant formula contaminated with MOAH was recalled in several European countries.

- 2021 : Cereals containing traces of MOSH were removed from shelves in Germany and the Netherlands.

- 2023 : EFSA proposes new limitations for oils and fats to avoid large-scale contamination cases

Manufacturers must therefore anticipate these controls by implementing rigorous analytical procedures and ensuring that their products comply current regulations .

Regulations surrounding mineral oil hydrocarbons are set to become stricter in the coming years, encouraging companies to adopt a proactive approach to limit contamination and ensure the health safety of their products.

Laboratory analyses for the detection of mosh and moah

Faced with the risks associated with food contamination by mineral oil hydrocarbons, laboratory analyses play a key role in identifying and quantifying the presence of MOSH and MOAH. These analyses allow manufacturers to ensure their products comply with current standards and to limit risks to consumer health.

What is Mosh Moah analysis?

MOSH/MOAH analysis is a set of analytical methods used to detect and quantify the presence of MOSH (saturated hydrocarbons) and MOAH (aromatic hydrocarbons) in food and its packaging.

Objectives of the analysis:

- Identify the presence and concentration of MOSH and MOAH.

- Differentiate between saturated hydrocarbons (MOSH) and aromatic hydrocarbons (MOAH).

- Determine the source of the contamination (packaging, additive, lubricant, etc.).

- Check that the food complies with current regulations.

These analyses are particularly important for the food industry , especially in the vegetable oil, cereal, chocolate and infant food , where contamination by MOH is common.

Analytical methods used in the laboratory

Analyzing hydrocarbons in mineral oils is complex because these substances form a mixture of chemical compounds with varying structures and molar masses. Laboratories therefore use advanced separation and detection techniques.

Liquid chromatography coupled with gas chromatography with flame ionization detector (LC-GC-FID)

- Principle : separation of MOSH and MOAH by means of a first step of liquid chromatography (LC), followed by a more detailed analysis by gas chromatography (GC).

- Detector used : flame ionization detector (FID), which measures the amount of hydrocarbons present.

- Advantages : very precise method allowing simultaneous analysis of MOSH and MOAH.

- Quantification limits : between 0.2 and 1 mg/kg depending on the product analyzed.

Liquid chromatography coupled with mass spectrometry (LC-GC-MS)

- Principle : after separation by liquid chromatography (LC), the hydrocarbons are analyzed via gas chromatography (GC) and then identified with a mass spectrometer (MS).

- Objective : precise identification of carcinogenic MOAHs , particularly those containing more than three aromatic rings .

- Use : indispensable for the detection of contaminants in infant foods and vegetable oils .

Fourier transform infrared spectroscopy (FTIR)

- Principle : technique based on the absorption of infrared light by hydrocarbon molecules.

- Use : allows for the rapid characterization of mineral hydrocarbons present in food packaging.

Migration tests for packaging

- Objective : to assess the amount of MOSH and MOAH that migrates from packaging into food .

- Method : the packages are placed in contact with a fatty food simulator and analyzed after a defined exposure time.

- Applicable standards : Regulation (EU) 1935/2004 on materials in contact with food.

These different techniques guarantee reliable and accurate detection of mineral oil hydrocarbons in consumer products.

Laboratory standards and accreditations

To ensure the reliability of the results , analyses of hydrocarbons in mineral oils must be carried out in accredited laboratories that comply with strict standards.

1. ISO 17025 Accreditation

- International standard guaranteeing the technical competence of analytical laboratories.

- Required for official analyses carried out as part of food control.

2. COFRAC Certification (French Accreditation Committee)

- Recognized in France for ensuring the quality and accuracy of analyses .

- COFRAC laboratories are authorized to deliver results that comply with European regulatory requirements .

3. Compliance with European regulations

- Analyses carried out according to the recommendations of EFSA and SCOPAFF .

- Compliance with maximum contamination thresholds to avoid product recalls .

Accredited laboratories offer manufacturers a guarantee of reliability that is essential to ensure consumer safety and avoid penalties in case of non-compliance.

Solutions to limit contamination by mosh and moah

Food contamination by mineral oil hydrocarbons (MOSH and MOAH) poses a major challenge for the food industry. To ensure product safety and comply with regulatory requirements, manufacturers must implement prevention strategies and rigorous controls . These solutions involve improving packaging, controlling manufacturing processes, and optimizing quality control analyses.

Functional barriers in food packaging

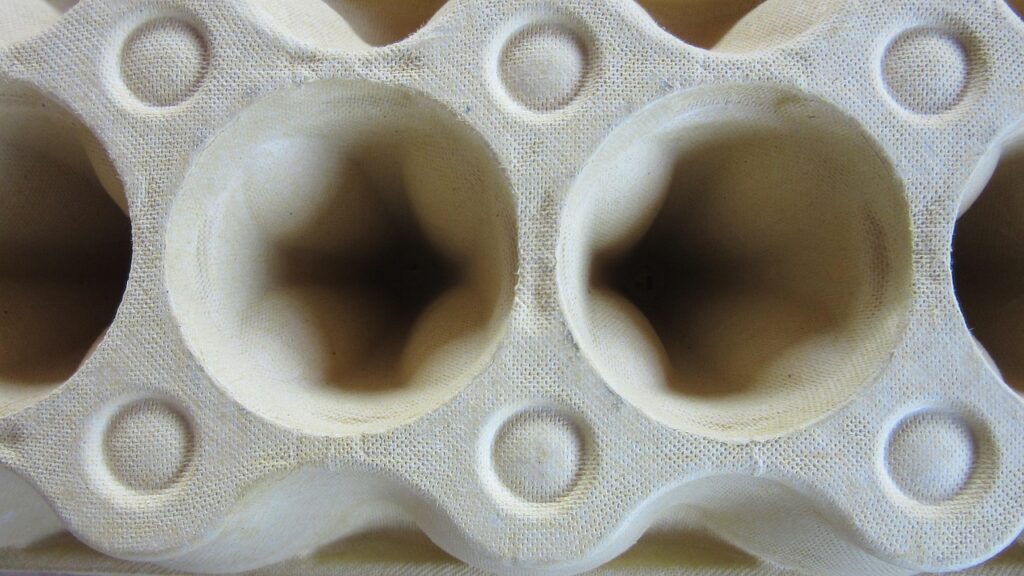

Food packaging is a major source of MOSH and MOAH contamination , particularly packaging containing recycled paper or mineral inks. To limit the migration of these substances into food, manufacturers are developing barrier solutions tailored to packaging materials.

1. Use of inner bags

Some foods are now protected by inner plastic bags (polypropylene or polyester) preventing direct contact between the food and the cardboard. This technique is used for cereals , rice, and bakery products .

2. Application of a barrier layer to the packaging

Manufacturers incorporate protective coatings inside cardboard packaging to prevent the migration of mineral hydrocarbons. These layers can be:

- Polymer films (PE, EVOH)

- Specific varnishes that block the migration of hydrocarbons.

3. Integration of functional absorbents into the cardboard

Some packaging incorporates specific absorbents that capture mineral hydrocarbons before they reach the food. These absorbents are often composed of modified clays or activated carbon .

EFSA recommends prioritizing these functional barriers reduce exposure to mineral oil hydrocarbons in food, especially food intended for children and infants.

Optimization of industrial processes

Besides packaging, MOSH and MOAH contamination can originate from manufacturing processes . Several measures can limit this exposure within production chains.

1. Use of compliant lubricants and technological aids

- Replacing conventional lubricants with NSF-H1 certified food-grade lubricants , which do not contain MOSH or MOAH.

- Monitoring of release agents and coating waxes , which may contain mineral hydrocarbons that do not meet food standards.

2. Raw material control

- Selection of suppliers guaranteeing raw materials free from contamination .

- Implementation of regular analytical tests to detect mineral hydrocarbons before incorporation into the production chain.

3. Monitoring of processing equipment

- Checking compressed air conveying systems , which can be a source of MOSH and MOAH if the lubricants used are not suitable.

- Regular cleaning and maintenance of equipment to prevent cross-contamination.

These measures significantly reduce the risk of contamination and ensure the conformity of food products.

The importance of analytical expertise with YesWeLab

YesWeLab plays a key role in supporting manufacturers to manage MOSH/MOAH risk. Through its network of specialized laboratories, the company offers precise analyses tailored to manufacturers' needs.

Why use YesWeLab for mosh and moah analysis?

YesWeLab is a major player in the analysis of hydrocarbons in mineral oils, thanks to its network of more than 200 partner laboratories in France and Europe.

Advantages of MOSH/MOAH analyses with YesWeLab

- Advanced analytical methods (LC-GC-FID, LC-GC-MS, migration tests) adapted to regulatory requirements.

- Fast and reliable service with a digital platform allowing real-time monitoring of analyses.

- Personalized support to identify sources of contamination and implement an effective control plan.

Analysis process with YesWeLab

- Request for analysis via the digital platform.

- Shipping samples.

- Contaminant analysis with a detailed report.

- Expert advice on interpreting results and improving product compliance.

Thanks to its expertise, YesWeLab helps food, cosmetics and packaging manufacturers comply with regulatory requirements and protect consumer health.

Laboratory analyses are now essential to control the risks associated with MOSH and MOAH. They ensure product safety , guarantee regulatory compliance , and prevent significant financial penalties .