The boiling point is a key concept in the physical and chemical sciences. It plays a crucial role in many industrial and scientific fields, ranging from food processing to analytical chemistry. Understanding this phenomenon and its implications allows for better control of various processes, such as the separation of mixtures, the characterization of substances, and the optimization of industrial processes. This article explores the fundamentals, measurement methods, and practical applications of this essential parameter.

1. Introduction

Definition of boiling point

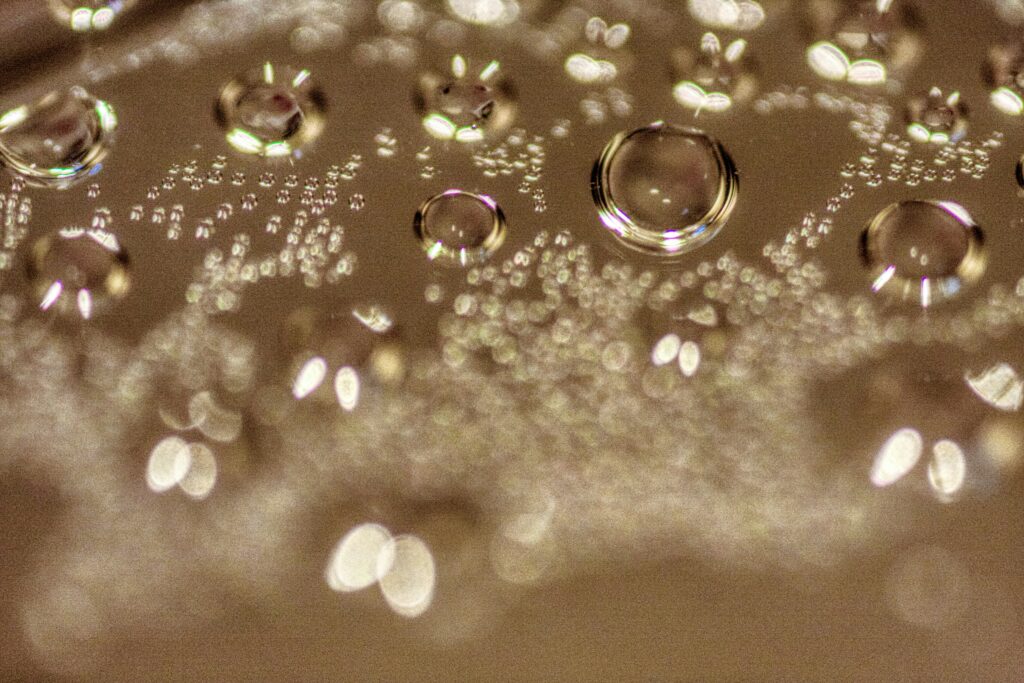

The boiling point is the precise temperature at which a liquid changes from a liquid to a gaseous state. This occurs when the saturated vapor pressure of the liquid equals the ambient pressure. Unlike evaporation, which is a surface process, boiling involves the formation of vapor bubbles within the liquid. These bubbles then rise to the surface, releasing the vapor into the atmosphere.

Importance of boiling point

The boiling point is a physical property characteristic of every substance. It allows us to identify pure compounds and understand their behavior under different conditions. For example, water boils at 100°C at sea level, but this temperature decreases at high altitudes due to the drop in pressure. Conversely, in a pressure cooker where the pressure is increased, water can boil at around 120°C, allowing for faster cooking of food.

Practical applications

Understanding boiling point is essential in many sectors. In the food industry, it is used to optimize cooking processes or to concentrate solutions, such as in maple syrup production. In the chemical industry, it is used to separate the components of a mixture by distillation. It is also a critical parameter in the formulation of cosmetic products, the manufacture of pharmaceuticals, and the analysis of environmental contaminants.

2. What is boiling point?

Transition from a liquid to a gas

The boiling point marks the point at which the energy supplied to a liquid becomes sufficient to break the intermolecular forces that hold the molecules in the liquid state. At this temperature, the molecules leave the liquid and transition to a gaseous state, creating vapor bubbles. These bubbles rise to the surface and release the vapor into the surrounding atmosphere.

The role of pressure in defining the boiling point

The boiling point depends directly on the pressure exerted on the surface of the liquid. Under normal conditions, defined as an atmospheric pressure of 101.3 kPa (1 atmosphere), each liquid has a characteristic boiling point. For example, water boils at 100 °C, while methanol, with weaker intermolecular forces, boils at approximately 65 °C.

When ambient pressure decreases, such as at high altitudes, the boiling point also decreases because less energy is required to equalize the surrounding pressure. Conversely, higher pressure, such as in a pressure cooker, increases the boiling point. This relationship between pressure and boiling is exploited in various industrial and scientific processes.

Difference between boiling and evaporation

Boiling is often confused with evaporation, although they are distinct processes. Evaporation is a surface phenomenon that occurs at all temperatures, even below the boiling point. Only molecules at the surface of the liquid, with sufficient kinetic energy, transition to a gaseous state. In contrast, boiling is a volumetric process where vapor bubbles form throughout the liquid when the temperature reaches the boiling point.

These distinctions are important for understanding thermodynamic phenomena and the applications of boiling point in analyses and processes. By mastering these concepts, it becomes possible to optimize physical and chemical transformations in various contexts.

3. Factors influencing boiling point

Impact of ambient pressure

Ambient pressure is one of the main determinants of boiling point. When pressure decreases, such as at high altitudes, the boiling point drops proportionally. For example, at the summit of Mount Everest, where atmospheric pressure is around 34 kPa, water boils at only 71 °C. This temperature drop has practical implications, particularly in cooking and industrial processes.

Conversely, an increase in ambient pressure, such as in a pressure cooker or during pressurized processes, raises the boiling point. This allows for faster chemical reactions or reduced cooking times by increasing the available thermal energy.

Influence of impurities on boiling point

The presence of impurities in a liquid alters its boiling point. This variation is known as ebullioscopy. For example, adding salt to water slightly raises its boiling point because the dissolved ions disrupt intermolecular bonds. This principle is used in the chemical industry to control reactions or separate components.

Complex mixtures exhibit more unpredictable behavior. In a solution containing several volatile compounds, the boiling point varies depending on the relative concentrations of the substances. These properties are used in fractional distillation, a key method for separating homogeneous mixtures.

Specific cases: high altitude and controlled pressure

At high altitudes, the drop in atmospheric pressure reduces the temperatures required to reach boiling point. This can pose challenges in everyday activities like cooking, where lower temperatures slow down the process. Conversely, in industrial settings where pressure is controlled, it is possible to manipulate the boiling point to maximize process efficiency, such as in vacuum distillation. This technique is widely used to process heat-sensitive compounds.

Are you looking for an analysis?

4. Measurement of boiling point in the laboratory

Distillation method

Distillation is a commonly used technique for measuring boiling point, particularly for pure liquids and homogeneous mixtures. In this method, the liquid is heated to boiling, and the resulting vapors are condensed and collected. The temperature is measured at the vapor level, allowing for the precise determination of the boiling point. This technique is essential in the chemical industry for separating and purifying substances.

Siwoloboff Method

The Siwoloboff method is a simple and effective approach to determining boiling point under controlled conditions. A sample is heated in a test tube containing a sealed capillary. The temperature at which bubbles cease to form and the liquid begins to rise in the capillary is the boiling point. This method is often used for substances with moderate boiling points.

Use of differential scanning calorimetry (DSC)

Differential scanning calorimetry (DSC) is an advanced method for measuring boiling point, particularly useful for complex or sensitive compounds. A sample is placed in a crucible and heated at a controlled rate. The enthalpy peak detected on the thermogram indicates the boiling point. This method is widely used for plotting phase diagrams and studying phase changes.

Importance of standardizing conditions

To ensure accurate results, it is essential to standardize measurement conditions. This includes controlling ambient pressure, using calibrated thermometers, and properly preparing samples. Particular attention must be paid to equipment such as ebulliometers and calorimeters, which should be regularly calibrated to prevent measurement errors.

5. Industrial applications of boiling point

Food industry: cooking and distillation

In the food , boiling point is crucial for optimizing cooking and concentration processes. For example, pressure cooking in pressure cookers allows for higher temperatures than under normal conditions, thus reducing cooking time and preserving nutrients. Furthermore, distillation is used in the production of alcoholic beverages and flavorings, where the boiling point of the components determines their separation.

Another example is the production of maple syrup, where water is evaporated at a controlled temperature to concentrate the natural sugar. This precise control ensures the quality of the final product while preventing unwanted caramelization.

Chemical industry: separation and purification

In chemical processes, boiling point is used to separate and purify complex mixtures. Fractional distillation, which relies on the differences in boiling points of components, allows for the recovery of pure substances from mixtures. This process is commonly used in petroleum refining, where hydrocarbons such as gasoline, kerosene, and diesel are extracted according to their boiling points.

In addition, recrystallization, a method used to purify solids, also exploits boiling point to remove liquid impurities.

Pharmaceutical industry: characterization of active substances

In the pharmaceutical field, the characterization of active substances often relies on their boiling point. This ensures the stability of compounds under different temperature conditions. For example, solvents used in drug synthesis are often chosen based on their boiling point, allowing for controlled evaporation and efficient recovery.

Boiling points are also taken into account when developing drying or crystallization processes for active ingredients, thus ensuring their purity and efficacy.

Cosmetics: stability and efficacy of formulations

In the cosmetics , boiling point plays a crucial role in product formulation. Thermal stability tests of creams, lotions, and makeup ensure that products remain effective and safe under varying conditions. Furthermore, volatile solvents used in certain formulations, such as sprays and varnishes, are selected based on their boiling point to guarantee rapid drying without compromising quality.

These applications demonstrate how crucial controlling boiling point is for ensuring the efficiency, quality, and safety of industrial products. By adapting processes to this parameter, companies can improve their performance while meeting regulatory requirements and consumer expectations.

6. Practical lists for manufacturers and researchers

Factors to monitor for reliable measurement

Accurate measurement of boiling point depends on several parameters that are essential to control. Here are the main elements to monitor:

- Maintaining constant pressure : Any variation in ambient pressure can skew the results. It is crucial to work in an environment where the pressure is stable, or to use equipment that allows control of this variable.

- Use calibrated equipment : Thermometers, calorimeters and other instruments must be regularly calibrated to ensure optimal accuracy.

- Check the purity of the samples : Impurities often alter the boiling point. It is important to work with samples that are as pure as possible to avoid unexpected variations.

- Prepare the sample correctly : Ensure that the volume is suitable for the equipment used and that the sample is homogeneous before measurement.

Laboratory equipment for measuring boiling point

The accuracy of the results also depends on the instruments used. Here is a list of tools commonly used to measure boiling point:

- High-precision thermometers : Used to accurately record temperature variations.

- Differential scanning calorimeters (DSC) : Ideal for detecting enthalpy peaks associated with the change of state.

- Ebulliometers : Designed specifically to measure the boiling point of liquids, including under controlled pressure conditions.

- Distillation systems : Used for analyses requiring the separation and purification of volatile compounds.